Hot Briquetted Iron (HBI), Steel’s Most Versatile Metallic: Part 3 – Assessing Product Quality

EDITOR’S NOTE

This article is the third in a series that has appeared in DFM throughout 2018. In Part 1, we went back to the basics and described what is Hot Briquetted Iron (HBI), what makes it such a useful source of steelmaking metallics, how it became part of MIDREX® Direct Reduction Technology, and where HBI plants are located. Part 2 in the series looked at where HBI can be sourced today and proposed considerations for where additional capacity could be built in the future. Part 3 discusses the parameters used to describe HBI quality and the various ways that HBI quality is determined.

ARTICLES IN THIS SERIES

Hot Briquetted Iron (HBI), Steel’s Most Versatile Metallic: Part 1 – Starting with the Basics

Hot Briquetted Iron (HBI), Steel’s Most Versatile Metallic: Part 2 – Sourcing Merchant HBI

*Note: This article is based on information contained in the IIMA Hot Briquetted Iron (HBI) Quality Assessment Guide, which is used with the permission and assistance of the International Iron Metallics Association (IIMA).

INTRODUCTION

Look at a definition of “quality” and most likely it will include the word “standard.” One source defines a standard as “an idea or thing used as a measure, norm, or model in comparative evaluations.” Another describes it as “a set of specifications that are adopted within an industry to allow compatibility between products.” In the case of Hot Briquetted Iron (HBI), both are relevant.

HBI has been manufactured commercially by four direct reduction processes: FIOR® and FINMET®, both fluidized-bed processes using iron ore fines, and MIDREX® and HYL/ Energiron®, which are shaft furnace processes using iron ore pellets and lump ores. All four processes primarily use natural gas as reductant and as fuel.

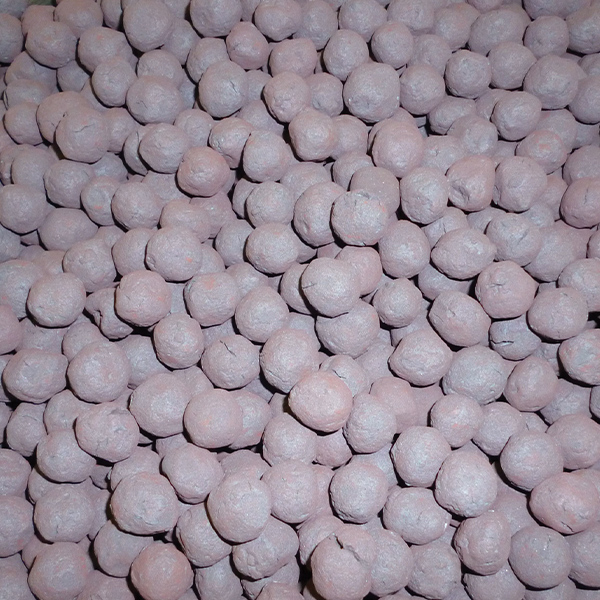

The physical and chemical properties of the HBI produced by the four processes are similar but not identical due to different feed-stocks and processing parameters. Typical HBI chemical specifications are listed in TABLE I.

TABLE I.

Typical HBI Characteristics

HBI, CDRI (cold DRI), and pig iron are known as ore-based iron metallics because they are manufactured from naturally-occurring iron ores. When these metallics are produced specifically to be traded and shipped, they are known as merchant iron.

International Iron Metallics Association (IIMA), the trade association for the various forms of ore-based iron metallics, has updated and posted on its website (www.metallics.org) a guide for assessing the quality of HBI, which was originally published in 2011 by HBI Association (HBIA), a predecessor of IIMA. The original guide was developed to better inform those involved in HBI production, trade, and use of the procedures and methods for sampling and testing the physical and chemical properties and the reactivity of the material. A goal of HBIA was to achieve consensus on a comprehensive set of standards through active involvement with the International Organization for Standardization (ISO) to establish quality criteria for all HBI traded globally.

IIMA has adopted the definition of HBI that is used by the International Maritime Organization (IMO) in its International Maritime Solid Bulk Cargoes Code (IMSBC Code), in which HBI is designated “Direct Reduced Iron (A) – Briquettes hot-moulded” and defined as follows:

Direct reduced iron (A) is a metallic grey material, moulded in a briquette form, emanating from a densification process whereby the direct reduced iron (DRI) feed material is moulded at a temperature greater than 650°C and has a density greater than 5,000 kg/m3. Fines and small particles (under 6.35 mm) shall not exceed 5% by weight.

SAMPLING AND SAMPLE PREPARATION

HBI samples for analysis should be drawn and prepared in accordance with the following international standard: ISO 10835: 2007 Direct Reduced Iron and Hot Briquetted Iron – Sampling and sample preparation (last reviewed and confirmed in 2016). This standard provides the underlying theory and the basic principles for sampling and preparation of samples, as well as the basic requirements for the design, installation, and operation of the systems for mechanical sampling, manual sampling, and preparation of samples taken from a lot under transfer to determine the chemical composition, moisture content, and physical properties of the lot.

The methods specified in ISO 10835:2007 are applicable to both the loading and discharging of DRI and HBI by means of belt conveyors or other ore-handling equipment to which a mechanical sampler may be installed or where stopped-belt sampling may be safely conducted. In the ISO standard, DRI includes both reduced pellets and reduced lump ore.

If it is not possible to perform sampling and sample preparation in accordance with ISO 10835:2007, sampling and sample preparation should be performed in accordance with the equivalent national standard or other relevant and applicable standards. In such circumstances, it is strongly recommended that the contractual parties first agree upon and document the sampling and sample preparation standards and procedures to be followed.

The following is a shortened and simplified overview of the sampling procedure.

Obtaining Sample Increments

FIGURE 1. Surveyors collecting increments using “stopped belt sampling” (images courtesy of Marine Inspection, LLC)

Sampling normally should be done by cutting a complete cross-section of the HBI stream at a transfer point while the material is being conveyed to or from a ship, stockpile, or container, using a mechanical sample cutter. The cutter aperture of the primary sampler should be at least three times the longest dimension of the HBI; i.e., at least 300 mm/11.8 in.

Increments also may be taken by “stopped-belt sampling” (see Figure 1). The conveyor must be shut down to sample manually and the location and procedure must be well defined in advance to ensure the safety of personnel. A cut is made to obtain material from across the full width of the belt, using a shovel and broom to collect fines. It is not recommended to sample from piles since obtaining a completely representative sample is difficult to achieve.

Often, flow of material along a belt will be started and stopped due to the upstream handling; for instance, a bucket is being emptied into a hopper feeding over the belt. The sample cut should not be taken near the beginning or near the end of flow. As a guideline, the sample should be taken from the middle third of flow.

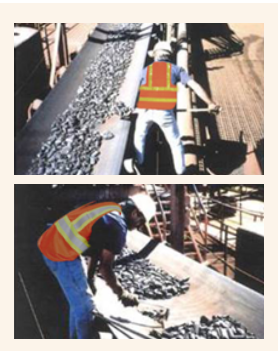

The number of sample increments will depend on the size of the shipment, the quality variation, and the desired sampling precision. HBI is normally shipped in vessels in the range of 15,000-40,000 tons (all tons are metric). The number of increments can be estimated using TABLE II as a guideline.

TABLE II.

HBI sampling increments (Reference: ISO 10835 Table 3)

Sampling for Particle Size Distribution

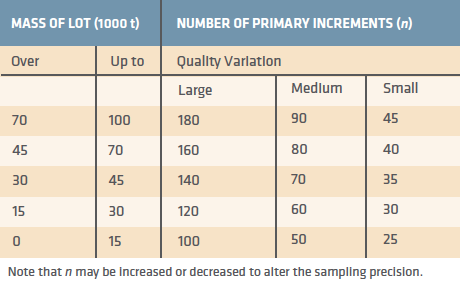

FIGURE 2. Screen size testing (images courtesy of Marine Inspection, LLC)

Sampling for analysis of particle size distribution may be performed in the field either during vessel discharge or following reload to conveyor belts for transport to the final customer (Figure 2). Typically, these are collected, photographed, and presented to the client along with size fraction percentage data and graphs to substantiate cargo quality guarantees by the supplier. Suitable sub-sample size fraction increments are: +37.5mm/+1.48 in, + 25mm/+0.98 in, +19mm/+0.75 in, +12.5mm/+0.5 in, + 9.5mm/0.37 in, +6.3mm/+0.25 in, +4.0mm/0.16 in, and – 4.0mm/-0.16 in.

Sample Preparation for Chemical Analysis

- The sample should be crushed to -12.5 mm/- 0.5 in in a primary jaw crusher.

- Homogenize and riffle out 1/4 of the sample (or as appropriate to reduce sample mass).

- Crush this further to -2 mm/-0.08 in in a secondary jaw crusher.

- Homogenize and riffle out 200-500 g/7.05-17.63 oz of material.

- Pulverize this sub-sample to 95% passing -150 µm for analysis. Precautions should be taken at this step to ensure that excessive heat is not generated in the sample which could change the chemical composition [temperatures less than 60°C/140°F are recommended], e.g. minimize grinding time, grind in small batches.

DETERMINING PHYSICAL QUALITY

(Note: Sampling for physical analysis can be considerably more stringent than sampling for chemical analysis. Therefore, it is recommended to refer to the ISO Manual for Sampling of Bulk Solids prior to attempting such sampling.)

The physical quality of an HBI briquette is mainly determined by its apparent density and strength. The water absorption also may be measured, although this is less frequently used. These properties and the relevant test methods are described in the following ISO standards:

- ISO 15968 – direct reduced iron – determination of apparent density and water absorption of hot briquetted iron (HBI).

- ISO 15967 – direct reduced iron – determination of tumble and abrasion indices of hot briquetted iron (HBI).

Apparent Density (ISO 15968)

In general, apparent density is determined in accordance with the Archimedes principle, which states that the apparent weight of an object when immersed in a liquid decreases by an amount equal to the weight of the volume of the liquid that it displaces. Since 1 ml (0.03 oz) of water has a mass equal to 1 g/0.04 oz when the object is immersed in water, the difference between the two masses (in grams) will equal almost exactly the volume (in ml/oz) of the object weighed. Therefore, knowing the mass and the volume of an object allows the density to be calculated.

Preparation of the test sample is of special importance in the case of HBI. This differs from the well-known Archimedes method for solid and non-porous test pieces in that the remaining open pores must be soaked in water before determining the apparent density. The main steps according to ISO 15968 are:

- Dry and weigh

- Soak, surface dry and weigh

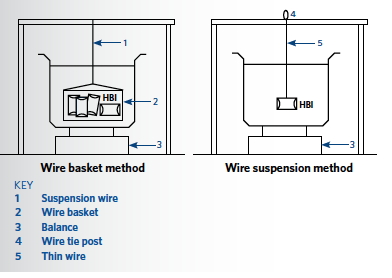

- Archimedes test (wire basket or wire suspension)

The results determined in this procedure are:

Apparent density ρa (basket method):

ρa = m1 / (m4-m3)

Apparent density ρa (wire suspension method)

ρa = m1 /m4

Water Absorption

α = (m2-m1)*100 / m1

Where:

- m1 is the mass in air, in grams, of the dried briquettes

- m2 is the mass in air, in grams, of the surface-dried, soaked briquettes

- m3 is the apparent mass in water, in grams, of the wire suspension basket. This is equivalent to the “apparent volume” of the basket. In the case of the wire suspension method, mass m3 is negligible

- m4 is the apparent mass in water, in grams, of the soaked briquettes. This is equivalent to the “apparent volume” of the briquettes

Further details concerning the relevant procedures are described in the ISO standard ISO 15968. Figure 3 is based on a diagram in this standard and illustrates the determination of the apparent density of briquettes in a water bath. As far as is known, all operating HBI plants utilize this procedure for the determination of briquette density.

FIGURE 3.

Examples of apparent density measurement apparatus

Briquette Strength (ISO 15967)

There are different options for the determination of briquette strength. In each case the intention is to simulate the briquette breakage and fines loss to be expected during transport and handling of the product.

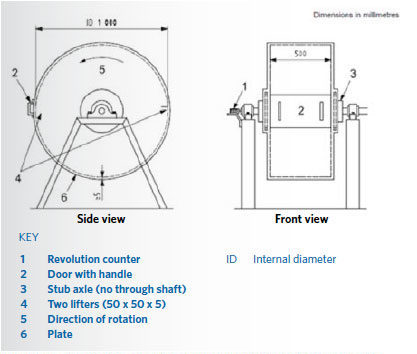

An ISO standardized procedure is described in ISO 15967 – direct reduced iron – determination of tumble and abrasion indices of hot briquetted iron (HBI). According to this standard, an abrasion drum with a diameter of 1,000 mm/39.37 in and a width of 500 mm/19.69 in with two lifters is used. Similar equipment is also used to test iron ore pellets and is illustrated in Figures 4 and 5. The rotational speed is 25 rpm. The test is finalized after 200 revolutions. According to ISO 15967 the following data are recorded or indicated:

- Tumble index: Percentage of the remaining material > 6.3mm /0.25 in after 200 revolutions of the drum

- Abrasion index: Material < 0.5 mm/0.02 in in percent after 200 revolutions

ISO 15967 does not contain a list of definitions but includes a cross reference to another standard, ISO: 11323 – iron ore and direct reduced iron – vocabulary. Relevant definitions are included at the end of this article.

It should be noted that several HBI plants have developed and apply procedures for determining briquette strength which deviate from ISO 15967. These can be divided into two general groups:

-

Tumble drum test

A drum, as described above, is used with the same or similar specifications for performing the “tumbling.” However, additional or different screen cuts are utilized.

-

Drop test

These are non-standardized drop tests, varying from one plant to another, with different drop heights and number of drops. Results are recorded and documented based on a screen analysis of the material after testing.

For further information about such tests, please refer to the relevant information provided by individual HBI plants.

FIGURE 4.

Tumble drum for determining the tumble and abrasion index

FIGURE 5.

Tumble drum for determining the tumble and abrasion index (ear protection required!)

DETERMINING CHEMICAL COMPOSITION

The chemical composition of HBI can vary depending on its origin. The iron ore used to produce HBI has the largest impact, but other factors such as the process technology also can influence its chemistry. This section presents the ISO standards and internationally recognized testing procedures that, when properly applied, define the chemical composition of HBI as a manufactured product.

The chemical composition of interest to the consumer includes iron (total iron, metallic iron), carbon, sulfur, phosphorus, and gangue (primarily CaO, SiO2, MgO and Al2O3), as they will impact how the HBI is melted and performs in subsequent products.

Sample Preparation

Reference: (ISO 14284:1996, Steel and iron – Sampling and preparation of samples for the determination of chemical composition) A representative sample (as described earlier in the Sampling and Sample Preparation section) of the HBI lot is further prepared for chemical analysis by grinding and splitting down to a size suitable for chemical analysis. HBI is a solid, non- homogeneous manufactured product so there is an inherent variability within a lot; careful sampling and sample preparation are critical to maintaining statistical representation necessary to the validity of the reported analyses. In addition, improper sample preparation techniques can alter the sample, leading to false results – for example, excessive heating of the sample during grinding will re-oxidize the metallic iron to iron oxide.

Total Iron

References:

- ISO 2597-1:2006, Iron ores – determination of total iron content – Part 1: Titrimetric method after tin (II) chloride reduction

- ASTM E246-10 (2015), Standard Test Methods for Determination of Iron in Iron Ores and Related Materials by Dichromate Titration

These test methods specify titrimetric methods for determination of total iron in iron ore but are commonly used for HBI as well. The ISO standard specifies a maximum iron content of 72% whereas the ASTM standard goes up to 95%.

Determination of total iron by XRF is commonly used but is not currently a standard.

Metallic Iron

References:

- ISO 16878: 2016 – determination of metallic iron – Iron (III) chloride titrimetric method

- ISO 5416:2006, Direct reduced iron – determination of metallic iron – Bromine-methanol titrimetric method

Both test methods specify titrimetric methods for determination of the mass fraction of metallic iron in reduced iron ores such as HBI and DRI. The ferric chloride method is applicable to mass fraction of metallic iron range 57.5-90.5% but is reliably used in higher range.

The bromine methanol method is applicable to a concentration range of 15-95% of mass fraction of metallic iron. The bromine methanol method is not recommended due to the hazards associated with bromine methanol and waste products, but it is useful for precision analysis on claims or clarification issues.

Determination of metallic iron by XRF and XRD is not recommended at this time and should only be considered as semi-quantitative.

Carbon/Sulfur

References:

- ISO 15350:2000 Steel and iron — determination of total carbon and sulfur content — Infrared absorption method after combustion in an induction furnace (routine method)

- ISO 9686:2006 Direct reduced iron – determination of carbon and/or sulfur – High frequency combustion method with infrared measurement

In the IR combustion method, the sample is burned in an oxygen atmosphere in an induction furnace. The carbon in the sample is oxidized to carbon dioxide (CO2) while the sulfur is converted to sulfur dioxide (SO2). Both CO2 and SO2 are then measured by infrared detectors. Several equipment manufacturers supply dedicated equipment for carbon/sulfur determination. HBI samples must be in powder form and of small size; sample uniformity is critical, and the test is often performed in replicates.

Cementite (Fe3C)

There are no standards for the direct determination of cementite. It is possible to estimate the amount of cementite in HBI by subtracting the free carbon measured using ISO 10719:2016 from the total carbon measured using ISO 15350:2000. The former standard is developed for cast iron and specifies a maximum of 3% carbon. Cementite also can be estimated by X-ray diffraction (XRD) but this method is considered semi-quantitative.

Phosphorus

References:

- ISO 4687-1:1992 Iron ores — determination of phosphorus content — Part 1: Molybdenum blue spectrophotometric method

- ISO 9516-1:2003 Iron ores — determination of various elements by X-ray fluorescence spectrometry – Part 1: Comprehensive procedure

Both methods were developed for iron ore but apply also to HBI. The X-ray fluorescence method is commonly used for routine analysis, but the accuracy depends on the quality of the calibration curves. The spectrophotometric method is used determine phosphorus when analyzing unknown samples.

Gangue (by X-ray fluorescence)

Reference:

- ISO 9516-1:2003 Iron ores — determination of various elements by X-ray fluorescence spectrometry — Part 1: Comprehensive procedure

Analysis of all gangue components in HBI – such as CaO, SiO2, MgO and Al2O3 – is performed primarily using the x-ray fluorescence (XRF) method developed for iron ore. Various other methods, such as titration, atomic absorption or inductively coupled plasma also exist, but are becoming obsolete.

ISO committees are working on a simplified method (ISO 9516-2) and procedures for internal standards (ISO 9516-3) but they are not finalized at this time.

DETERMINING REACTIVITY

HBI is produced by compacting Direct Reduced Iron (DRI) in a roller press at elevated temperature

(> 650°C/1202°F). This is done to reduce the reactivity of the DRI and to minimize yield loss in the form of fines during shipping, handling and storage. DRI reactivity consists of two main reactions: oxidation and hydrogen generation. Both reactions are accelerated by the porous structure of DRI (i.e. very high surface area):

- Oxidation – the reaction of iron metal with oxygen, according to 2Fe + 3/2 O2 = Fe2O3 (Reaction 1). This reaction is exothermic 12.17.18 (generates heat) and may not dissipate fast enough in DRI stored in bulk, resulting in localized hot spots. As the temperature rises, the reaction accelerates until no oxygen oxygen is present.

- Hydrogen generation – when water dissociates in contact with DRI, according to the reaction Fe + 2H20 = Fe(OH)2 + H2 (Reaction 2). This reaction is endothermic (absorbs heat) and it is slow at room temperature, but accelerates with increased temperature, such as when water is in contact with hot DRI. In the presence of a flame, sufficient quantities of hydrogen will burn or explode. The described reaction is even more pronounced and critical when it comes to contact with seawater.

Depending on the conditions, both reactions can happen simultaneously, where oxygen is both consumed and generated, and hydrogen is produced. Reaction 1 raises the temperature while Reaction 2 cools the DRI.

Hot briquetting reduces available inner surface and porosity. At an apparent density of 5,000 kg/m3 or higher, the IMO in effect deems the reactivity to be sufficiently reduced for safe shipment of HBI as per the IMSBC Code schedule for DRI (A). The remaining porosity in HBI is mostly a function of pressing force and temperature and is lower than DRI. Because of the drastic reduction in the exposed surface area, the kinetic rate of the chemical reactions above is reduced significantly, making HBI much less reactive than DRI.

There are currently no standard methods for testing HBI reactivity specifically. Most of the test protocols were developed for DRI but have not been standardized by ISO or other organizations. IIMA can provide reference to these tests if requested: the more common are the Nagel tests and the reactivity tests developed by technology providers Midrex and Tenova/HYL.

OTHER PHYSIO-CHEMICAL TESTS

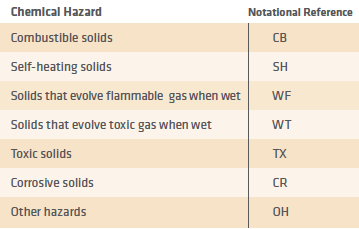

In the IMO’s IMSBC Code (mentioned earlier in the Introduction section), the following hazards are said to be applicable to Materials Hazardous only in Bulk (MHB):

A material must be classified as MHB if the material possesses one or more of these chemical hazards. When a test method is prescribed in the Code, representative samples of the cargo to be carried must be used for testing, samples to be taken 200-360 mm/7.87-14.17 in inward from the surface at 3 m/9.8 ft intervals over the length of a stockpile.

The IMO requires testing for these hazards in accordance with the United Nations publication “Recommendations on the TRANSPORT OF DANGEROUS GOODS: Manual of Tests and Criteria.” In some cases, these tests have been shown not to be wholly reliable for assessment of MHB hazards for some cargoes and IIMA therefore recommends caution.

For this reason, the “indirect approach” for determining critical limits for safe shipping of HBI in bulk as specified in the Direct Reduced Iron (A) schedule of the IMSBC Code continues to be the preferred approach for the HBI industry. This schedule defines the much simpler and more reliable measurable parameters of density (>5,000 kg/m3), proportion of fines below 6.35 mm/0.25 in (maximum 5% by weight) and briquetting temperature (>650°C/1202°F). These limits reflect not only research by industry prior to the introduction of HBI as a commodity, but also the many subsequent years of experience with global shipment of HBI.

TERMS OFTEN ASSOCIATED WITH HBI QUALITY

(ISO 11323:2010, Iron ore and direct reduced iron – Vocabulary)

-

Air-dried sample

Sample whose moisture is nearly equilibrated with the laboratory atmosphere.

-

Apparent Density

Ratio of the mass in air of a particle of iron ore or hot briquetted iron to its apparent volume. NOTE: Apparent density is referred to as “ρa” and expressed in grams per cubic centimeter.

-

Apparent Volume

Volume of iron ore or hot briquetted iron, including the volume of any closed and open pores

-

ASTM Standards

Technical standards for a wide range of materials, products, systems, and services developed and published by ASTM International.

-

Bulk Density

Mass in air of a unit volume of particles of iron ore or direct reduced iron as aggregate, which includes the voids between and within the particles.

NOTE 1: Bulk density is referred to as “ρb” and expressed in kilograms per cubic metre.

NOTE 2: In industrial practice, the bulk density of iron ore or direct reduced iron is expressed as the ratio of the mass to the volume of a measuring container filled under specified conditions. -

Closed Pores

Voids within a particle not connected with its outside environment.

-

Degree of metallization

Relative measure of the amount of metallic iron (8.5) in the total iron content of direct reduced iron.

NOTE 1: ISO 11257, applicable to direct reduction feedstocks, determines the degree of metallization, referred to as M, expressed as the ratio of the metallic iron content at a reduction time of 300 min, to the total iron content, as a percentage by mass. NOTE 2: ISO 11258, applicable for direct reduction feedstocks, determines the degree of metallization referred to as MR, expressed as the ratio of the metallic iron content at a reduction time of 90 min, to the total iron content, as a percentage by mass. -

Degree of Reduction

Extent to which oxygen has been removed, under specific reduction conditions, from iron oxides, expressed as the ratio of oxygen removed by reduction to oxygen originally combined with iron.

NOTE 1: ISO 7215, applicable to blast furnace feedstocks, determines for a reduction time of 3 hours the degree of reduction referred to as the final degree of reduction expressed as a percentage by mass.

NOTE 2: ISO 11258, applicable to direct reduction feedstocks, determines for a reduction time of 90 min the degree of reducion referred to as the final degree of reduction expressed as a percentage by mass.

NOTE 3: The final degree of reduction is generally denoted by Rf. -

Direct Reduced Iron (DRI)

High grade feed for iron and steelmaking obtained from the reduction of natural or processed iron ores, without reaching the melting temperature.

-

Drop Test (a.k.a. Shatter Test)

Test used to determine the physical strength of bulk materials, such as coal, coke, sinter, iron ore pellets, and HBI. Material is dropped from a certain height a certain number of times and the fraction of +20mm/0.79 in is screened out. The percentage of material larger than 20mm/0.79 in is reported as the drop strength.

-

Hot Briquetted Iron (HBI)

Known as Direct Reduced Iron (A) Briquettes, hot-moulded in the IMO IMSBC Code. HBI is produced by reducing iron oxide lumps, pellets, or fines, and compressing the material at a temperature of at least 650°C/1202°F to achieve an apparent density of at least 5,000 kg/m3.

-

International Maritime Bulk Cargoes (IMSBC) Code

Guidelines published by IMO that embody the best practices for the loading and unloading of ships and informs seafarers about the risks associated with bulk cargoes.

-

International Maritime Organization (IMO)

A United Nations agency responsible for regulating the safety of international ocean shipping of bulk cargoes.

-

International Organization for Standardization (ISO)

An international standard-setting body composed of representatives from various national standards organizations to promote worldwide proprietary, industrial and commercial standards.

-

Merchant Iron

DRI, HBI, and pig iron, which are manufactured, traded, and shipped internationally (typically by ocean transport) for use in making steel. Most merchant iron is produced by plants dedicated to exporting the material; however, some direct reduction plants and blast furnaces export when they have excess iron capacity.

-

Metallic Iron

Iron present in its non-oxidised state, with zero oxidation number.

-

Metallization

Percentage of total iron in HBI present as metallic iron.

-

Open Pores

Voids within a particle connected with its outside environment.

-

Oven-Dried Sample

Sample that has been dried to constant mass at 105°C/221°F in an oven.

-

Total Iron

All iron present in any form, free and combined with oxygen or other elements

-

True Density

Particle density, which considers porosity of the material.

-

Tumble Strength

Resistance of lump ore, agglomerates or hot briquetted iron to size degradation by impact and abrasion, when subjected to tumbling in a rotating drum under specific conditions.

NOTE: In ISO 3271 and ISO 15967, tumble strength is referred to as the tumble and abrasion indices:

a. the tumble index is a relative measure of the resistance of lump ore, agglomerates or hot briquetted iron to size degradation by impact, referred to as “TI” and expressed as the percentage by mass of the 6.30 mm/0.25 in fraction generated in the test portion after tumbling.

b. the abrasion index is a relative measure of the resistance of lump ore, agglomerates or hot briquetted iron to size degradation by abrasion, referred to as “AI” and expressed as the percentage by mass of the −500 μm fraction generated in the test portion after tumbling. -

Tumble Test

Test in which material is rotated in a drum and the fraction of 6.35 mm is screened out. The percentage of the material larger than 6.35 mm/0.25 in is reported as the tumble strength. The fines fraction (less than 0.5 mm/0.02 in) is reported as the abrasion index.

-

Water Absorption

Mass of water at a specified temperature that is absorbed into the open pores of dry hot briquetted iron. NOTE: In ISO 15968, water absorption is expressed as a percentage of the dry mass.

IIMA Disclaimer – The information presented in the IIMA guide is intended as general information only and should not be relied upon in relation to any specific application. Those making use thereof or relying thereon assume all risks and liability arising from such use or reliance.