Off and Running

1960s

-

Donald Beggs, head of Surface Combustion’s R&D Group, conceives the idea for the MIDREX® Process

-

Start-up of first MIDREX Plant – Oregon Steel Mills, Portland, OR, USA

Crossing Continents

1970s

-

Korf Group purchases MIDREX Process and establishes Midrex Corporation in Charlotte, NC, USA

-

In-situ reforming

-

Heat recovery system

-

Furnace capacity increased up to 750,000 t/y

-

Flowsheets developed for coal and coke oven gas and high sulfur ores

-

Start-up of Hamburger Stahlwerke (now ArcelorMittal Hamburg) – oldest operating MIDREX Plant

-

MIDREX Plants produce more than 50% of world’s DRI

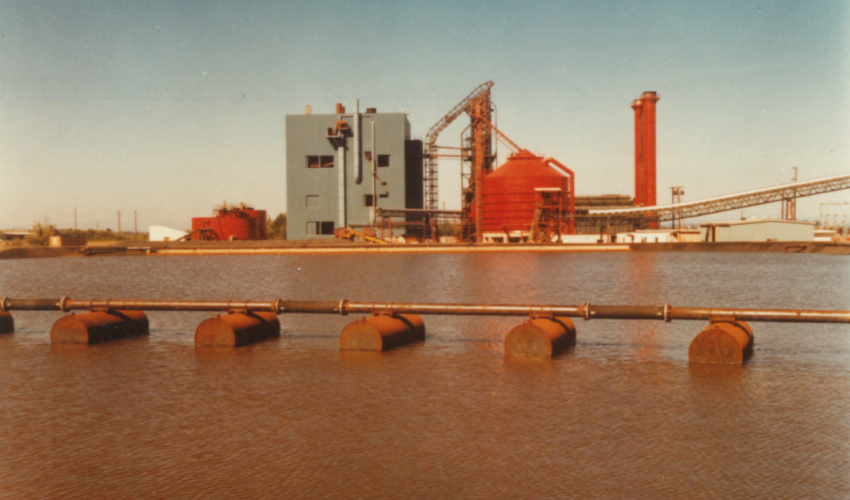

Leading the DRI Market

1980s

-

Kobe Steel Ltd. acquires assets of Midrex Corporation

-

Hot discharge furnace designed

-

First MIDREX Plant use of oxide coating – OEMK, Stary Oskol, Russia

-

Furnace capacity increased to 1 million t/y

-

Start-up of first MIDREX Hot Briquetted Iron (HBI) plant – Sabah Gas Industries (now Antara Steel Mills), Labuan Island, FT, Malaysia

-

MIDREX Plants produce more than 60% of world’s DRI

Continued Growth

1990s

-

MIDREX Plants produce 10 million tons of DRI in single year

-

First dual discharge MIDREX Plants – CDRI & HDRI (Essar Steel I and II, now ArcelorMittal Nippon Steel I and II)

-

First MIDREX Plant to use hot transport/hot charging of DRI – Essar Steel, Hazira, India

-

First MIDREX Plant use of oxygen injection – Acindar, Villa Constitucion, Argentina

-

MIDREX Plants produce 20 million tons of DRI in single year

-

Start-up of first MIDREX Plant using coal synthesis gas (from COREX® Process) – Saldanha Steel (now ArcelorMittal South Africa), Saldanha Bay, South Africa

-

Start-up of first single-module MIDREX MEGAMOD® Plant rated for 1 million t/y of DRI – Nippon Denro Ispat (now JSW Dolvi Works), Raigad, India

Setting World Records

2000s

-

First use of a hot conveyor for transporting & charging HDRI to an EAF – Hadeed E, Al-Jubail, Saudi Arabia

-

MIDREX Plants produce 30 million tons of DRI in single year

-

First installation of OXY+® partial oxidation system – OEMK, Stary Oskol, Russia

-

Start-up of first MIDREX Combination Plants (HDRI/HBI and CDRI on demand) – Hadeed E, Al-Jubail, Saudi Arabia, and Qatar Steel II, Mesaieed, Qatar

-

MIDREX Plants exceed 500 million tons of cumulative DRI production

Nonstop Innovation

2010s

-

Start-up of first Midrex HOTLINK® plant for direct charging of hot DRI (HDRI) into EAF – Jindal Shadeed, Sohar, Oman

-

MIDREX Plants exceed 1 billion tons of cumulative DRI production

-

Start-up of first MIDREX MxCōl® Plant to use coal gasification technology to make reducing gas – Jindal Steel & Power, Angul, India

-

Start-up of world’s largest HBI plant (2 million t/y) – voestalpine Texas, Corpus Christi, Texas

-

Start-up of world’s largest single module combination DRI plant, rated at 2.5 million t/y of CDRI/HDRI – Tosyali Algerie, Oran, Algeria

-

Midrex and Praxair develop and demonstrate Thermal Reactor System (TRS) for making reducing gas from coke oven gas

-

ACT™ (Adjustable Carbon Technology) – increases carbon (up to 4.5%) in new or existing MIDREX Plants without temperature loss

-

Flowsheets developed for hydrogen addition (MIDREX Flex™) and 100% hydrogen-based direct reduction (MIDREX H2™)

-

50 years of commercial operation

2020s

-

Midrex & AMI team up to offer DR-EAF process optimization

-

First commercial-scale MIDREX Plant (AM Hamburg) turns 50

-

Midrex certified for ISO 9001:2015

-

40th anniversary of Direct From Midrex

-

ArcelorMittal & Midrex collaborate in hydrogen steelmaking demonstration (AM Hamburg)