thyssenkrupp Steel Receives Construction Approval For Hydrogen-Ready DRI-Smelter Project

thyssenkrupp Steel Europe AG (TKS) has received approval from the Düsseldorf district government for early start of construction of the first direct reduction plant for hydrogen-based steel production.

The approval notice is an important milestone in the approval process. Final approval is expected by the end of 2024.

“We are very pleased that the Düsseldorf district government has approved our application for an early start of construction so quickly,” Dr. Arnd Köfler, Chief Technology Officer at TKS, said. “This means that we have cleared another important hurdle towards the realization of the first direct reduction plant at the Duisburg site and are taking a big step forward on the path to climate-neutral steel production.”

Now that the construction site preparation work has been completed, foundation work for the direct reduction plant can begin. Over the next few months, a veritable factory town almost 40 football pitches in size will be built on the site. The main part of the complex will be around 140 meters high and will be flanked by about 60 buildings. Up to 2,000 people will work on the construction site.

Background

The contract for the construction of a direct reduction plant plus two smelters awarded to the SMS group in consortium with Midrex Technologies, Inc. in spring 2023, was the largest single order in TKS history and launched one of the largest industrial decarbonization projects worldwide. TKS has received a funding decision from the federal and state governments totaling around two billion euros for its tkH Project, and TKS’s own investments will amount to just under one billion euros.

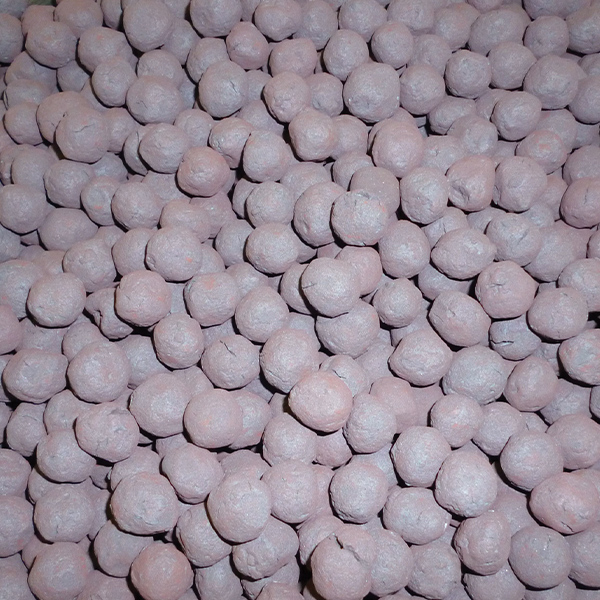

The tkH Project will integrate a technologically new plant combination into Europe’s largest steel mill, which will allow subsequent process steps in the green transformation of the steel mill. The 100% hydrogen-capable direct reduction plant with two smelters will have the production capacity of 2.5 million metric tons of direct reduced iron (DRI) per year. The plant can be operated with natural gas during the transition and with around 143,000 tons of hydrogen per year as early as 2029. The direct reduction plant will then save up to 3.5 million tons of CO2 per year and thus make an indispensable contribution to achieving the climate targets. The green transformation of steel production will secure good, sustainable jobs at the Duisburg site.

thyssenkrupp Steel launches tender to supply hydrogen to the first direct reduction plant in the tkH2Steel decarbonization project