H2 Green Steel Story – the Quest for Earth’s Sustainable Future

INTRODUCTION

In 2014, Vargas Holding, the founder and largest shareholder of H2 Green Steel, was established for the purpose of facilitating the transition to a more sustainable future by transforming sectors of society to emit less carbon. The mission of Vargas is to build new, sustainable companies from the ground up, free of legacy commitments, populated by people who share a passion for creating change.

Polarium, a firm that provides battery backup solutions for the telecommunications sector, was the first business established by Vargas in 2014. As Polarium grew, it became increasingly clear to management that sole-sourcing battery cells from Asia was an unsustainable business model for a company headquartered in Sweden.

To determine the viability of constructing a greenfield giga-scale lithium-iron battery manufacturing facility in Europe, Vargas Holding reached out to Pete Carlsson, formerly the Head of Supply Chain at Tesla Motors, and Northvolt was established. Located in northern Sweden, Northolt began manufacturing battery cells and made its first commercial sale in April 2022.

With Volkswagen as a major stakeholder, the automaker’s goal of achieving full decarbonization of the industry inspired Northvolt to explore the green steel market. Its business strategy calls for collaboration in product development, process technology, recycling methods, and logistics. The knowledge and expertise gained through the creation of Northvolt were instrumental in the founding of H2 Green Steel.

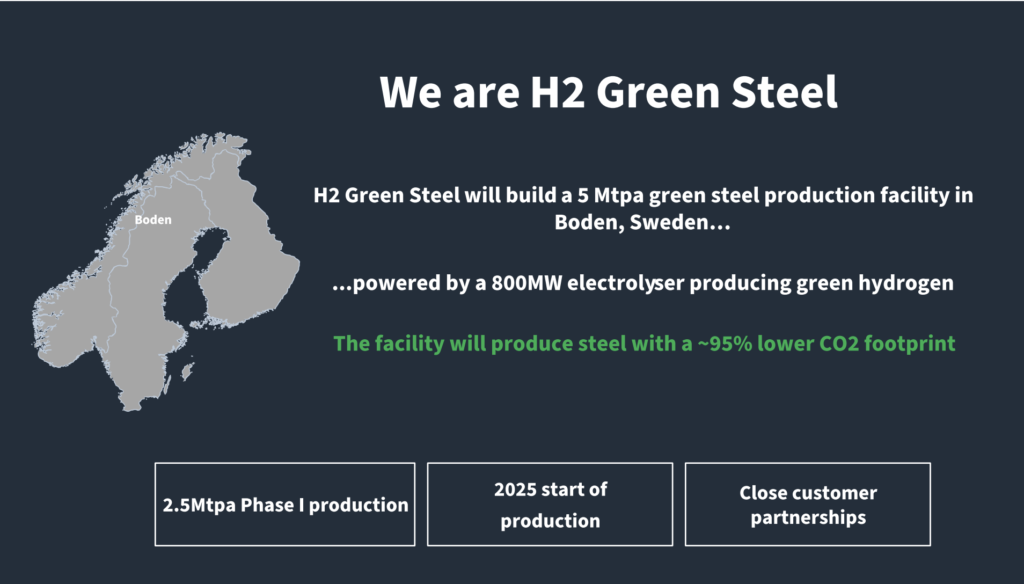

H2 Green Steel (H2GS AB) was established in 2020 with the ambition to accelerate the decarbonization of the steel industry using green hydrogen. The company’s main purpose is to radically reduce CO2 emissions in hard-to-abate industries. And because the steel industry is one of the world’s largest carbon dioxide emitters, we made the decision to start with steel.

H2 GREEN STEEL – THE FIVE-STEP PROCESS

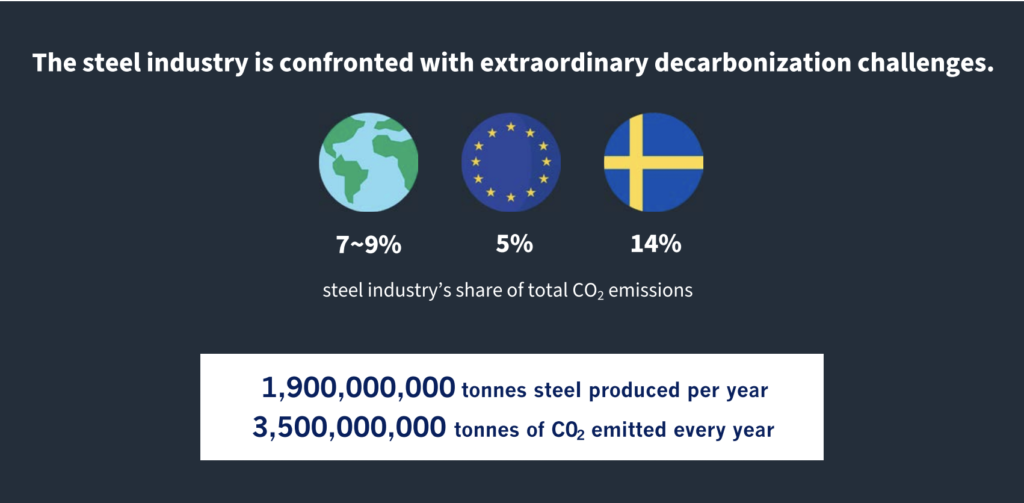

Production of steel is responsible for up to 9% of global CO2 emissions and 14% of Sweden’s total CO2 emissions. The European carbon market has involved steel companies since the carbon market began in 2005. However, steel companies have free carbon allocations due to the heavy industry feature, but free carbon allocations for steel companies will be dismissed by 2030 due to the “Fit for 55” plan.

To achieve net zero CO2 emissions by 2050, total global emissions must be reduced 37% by 2030. Achieving this target will take more than just increasing material or process efficiencies. It will require new technologies to be deployed at scale for the Industry Sector to contribute 13% of the emissions reduction in 2030.

As it stands now, steelmakers have three options:

- Do nothing,

- Invest in carbon capture and storage solutions, or

- Transition to cleaner production processes, such as hydrogen-based steelmaking starting with the direct reduction process.

Decarbonization of steel is not just about electrification to make hydrogen. It requires unique solutions to deal with emissions both from traditional blast furnace-based iron reduction process due its reliance on coal, as well as from high-temperature combustion based on natural gas.

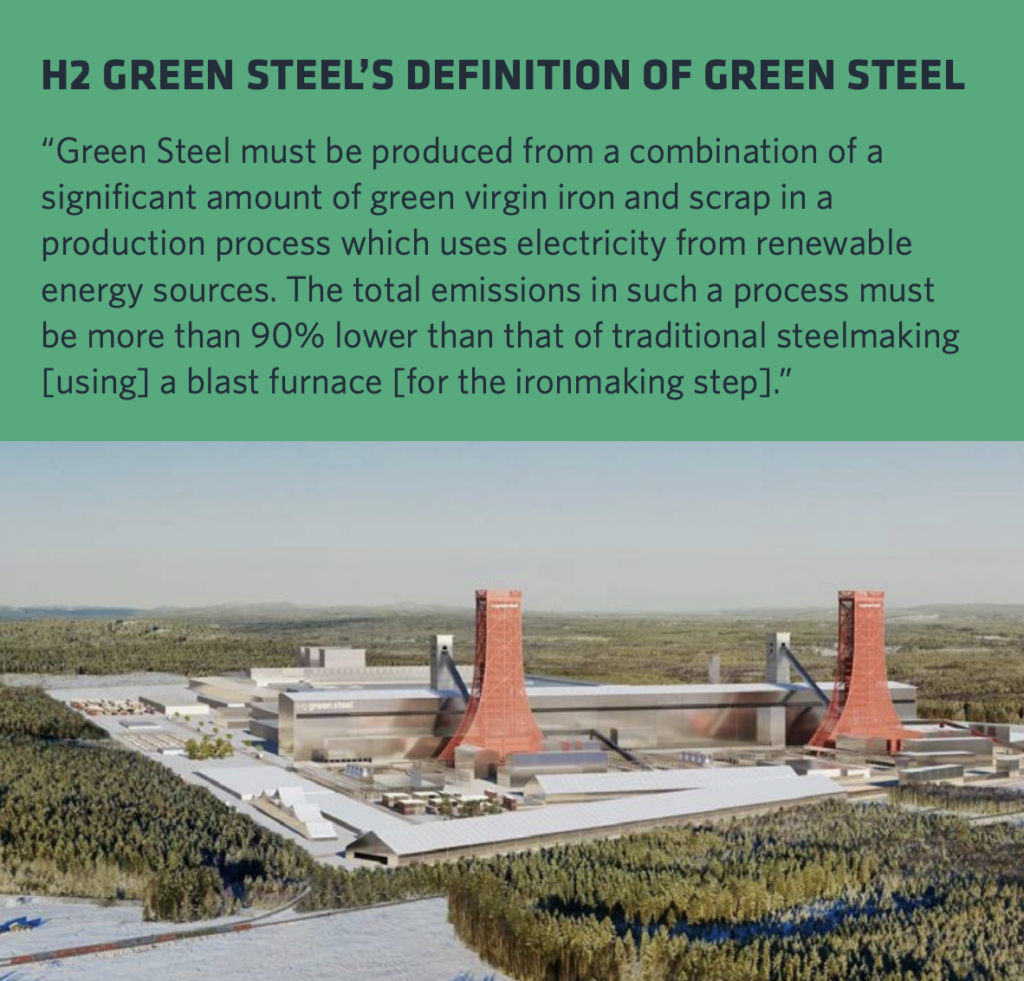

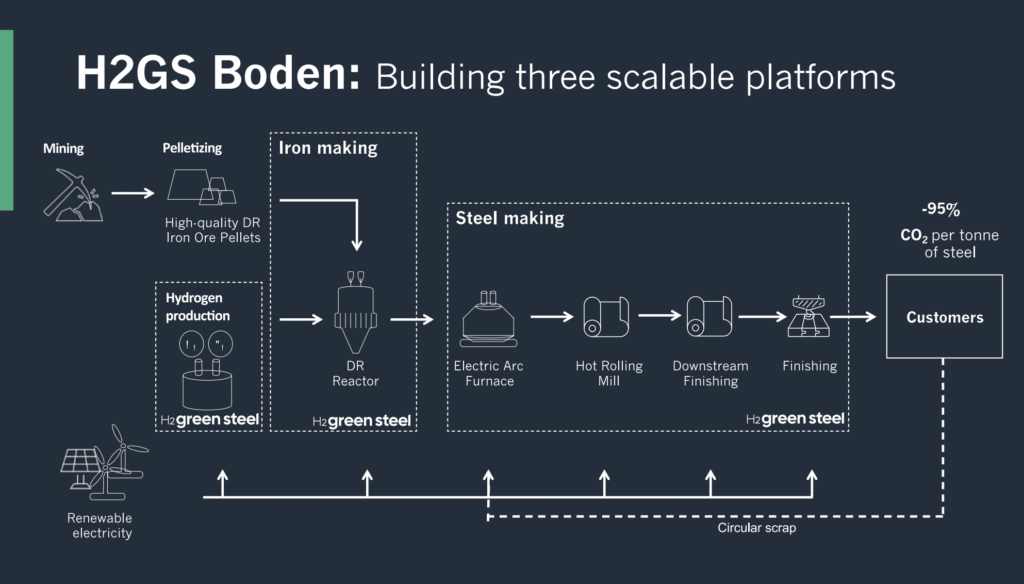

H2GS is pursuing a 5-step process to achieve green steelmaking (see sidebar for H2GS’s definition of “green steel”):

Step 1: Giga-scale Electrolysis –

Using fossil-free electricity to decompose water into hydrogen and produce enough hydrogen to make 5 million tonnes of high-quality steel annually by 2030.

Step 2: Hydrogen-based Direct Reduction –

Using green hydrogen instead of coal or natural gas to react with oxygen in iron oxide pellets to produce highly metallized direct reduced iron (DRI) for steelmaking with steam as the residual, thus reducing CO2 emissions by more than 95%.

Step 3: Electric arc furnace (EAF) Steelmaking –

Using fossil-free electricity to heat DRI and steel scrap to create liquid steel, with contained carbon in the slag playing an important role in lowering electricity consumption and enabling the transformation of iron to steel.

Step 4: Continuous Casting and Rolling –

Allowing energy consumption to be reduced 70% and replacing natural gas in the traditional process.

Step 5: Downstream Finishing Lines –

Cold rolling, annealing, and hot-dip galvanizing for adjusting steel thickness, creating desired mechanical properties, and protecting against corrosion, respectively.

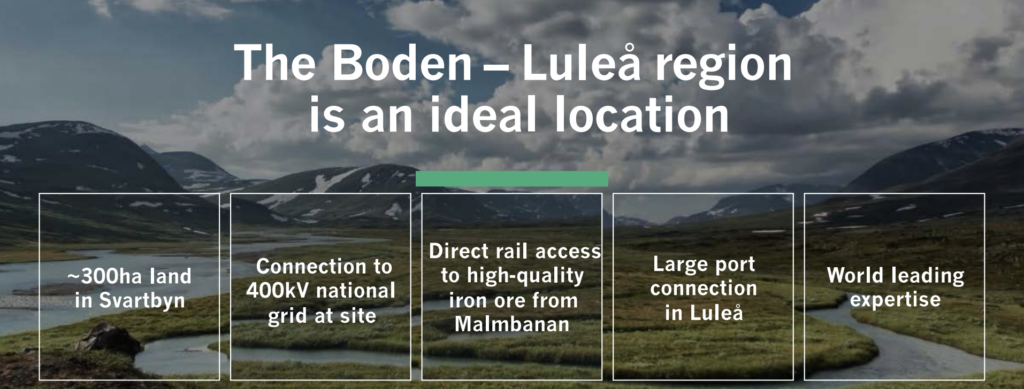

WHY CHOOSE BODEN

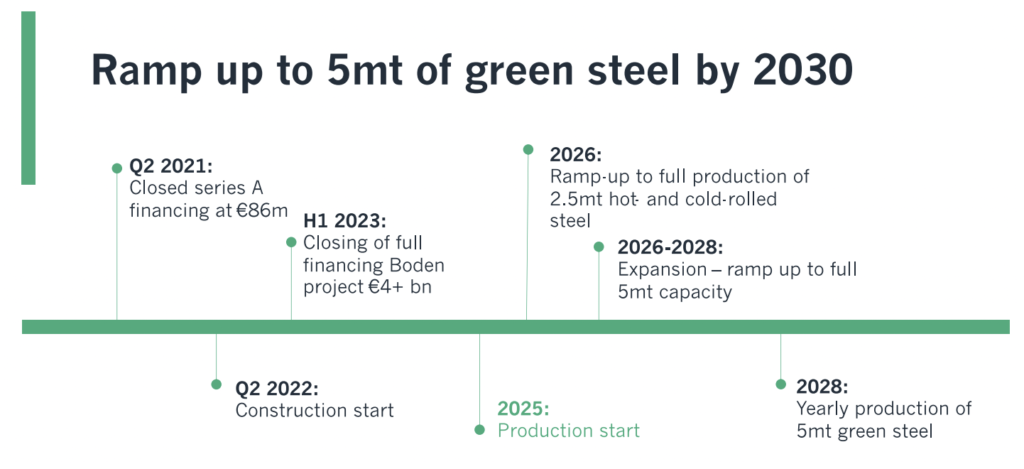

H2GS is building its first factory in Boden, a town 45 miles south of the Arctic Circle in the north of Sweden, in an area with one of Europe’s lowest energy costs. Green electricity is one of Boden’s biggest enablers and makes up about 90% of the energy mix. The cost of electricity is at a level that helps make steel produced with hydrogen DRI competitive. The site will include one of the biggest green hydrogen electrolysers, at 800MW, a MIDREX H2™ DRI plant, and a downstream steel mill supplied by the SMS Group.

Work is underway at the site, with the intention of installing roads and building temporary office space and housing for construction workers before the onset of winter 2022. A direct rail line will connect the Boden site to Luleå port, which will be able to accommodate ships equipped for icebreaking to ensure year-round operations. The steel mill will have 1,200-1,400 employees to produce 2.5 million tonnes of steel products.

Boden will be H2GS’s first lighthouse project. We see our project as equally an investment in green steel and as a building block for a green society, making the Norrbotten region a world leader in fossil-free steel production.

A TRANSFORMATION COMPANY WITH STEEL AS A PART OF IT

H2GS’s initial notion was that its steel project would only target vehicle makers since the auto sector was ready to pay a green premium. However, since then the company has expanded its horizon, as the impact and influence of decarbonisation continues to take hold globally.

What we do and strive to comprehend is not just the customer and the customer’s business but also the customer’s customer. And this is something that we are incorporating into our work with green steel as well. So, yes, the customers are on board and quite a wide range of customers, too. They are not just automotive and vehicle manufacturers, but also white goods & industrial equipment manufacturers that are prepared to pay a higher price for green steel for the future of our planet.

As a clear sign of a strong customer demand for green steel, H2GS has already signed long-term offtake supply agreements for over 1.5 million tonnes of steel that we will produce from 2025 onwards.

STRENGTHENING THE VALUE CHAIN

To establish a clean hydrogen-based steel ecosystem, the creation of a value chain is crucial. The ecosystem also requires the efforts of renewable energy, clean hydrogen, and technology solution providers, as well as the downstream consumer side to further reduce costs and develop markets.

Hydrogen-based steel production, especially with green hydrogen, is one of the most promising solutions for steel industry decarbonization, considering both clean efficiency and technology maturity. This route has nearly full potential of decarbonization and has been piloted by several steel companies.

The H2 Green Steel site will be a close to 300 hectares greenfield project in Boden in the Swedish Norbotten region. The plant is expected to produce green steel by 2025, ramping up volumes in 2026.

H2 Green Steel recently announced a signed agreement with Midrex Technologies, Inc. (Midrex) and Paul Wurth, an SMS Group company to supply the world’s first commercial 100% hydrogen direct reduced iron plant. MIDREX H2 is ironmaking technology for the new era, which will utilize green hydrogen produced from renewable energy to reduce iron ore. The DRI plant will have a yearly production capacity of 2,1 million tonnes of hot DRI and hot briquetted iron (HBI), which will feed the production of initially 2,5 million tonnes of green steel.

SMS Group will supply process technology for the world’s first large-scale green steel production plant including an electric arc furnace (EAF) melt shop, continuous casting and a hot rolling plant, as well as an advanced cold rolling and processing complex for the production of advanced high strength steel and automotive steel grades.