The Versatile OBM (Ore-Based Metallic): Part 1 – Everything you ever wanted to know about Direct Reduced Iron … but were afraid to ask!

EDITOR’S NOTE:

Direct reduced iron (DRI) has been around forever. Well maybe not forever, but long enough that everyone should know pretty much everything about it, right? Maybe not.

I put forth a notion that the steelmaking industry “assumes” that everyone knows the basics of direct reduction iron and DRI products.

Commercial DRI plants came into play mid-20th century at very meager tonnages, but by the end of the century DRI facilities got bigger, and more and more steelmakers began to use and make DRI products. The first 40-50 years for many was the ramping up of the industry or the birth of it depending on your perspective. Even today, DRI products represent a fraction of the world’s total iron production. Two years ago total world output set a new record at 75 million tons of DRI produced, which sounds massive until you realize blast furnaces produced nearly 1.5 billion tons.

THE BASICS…

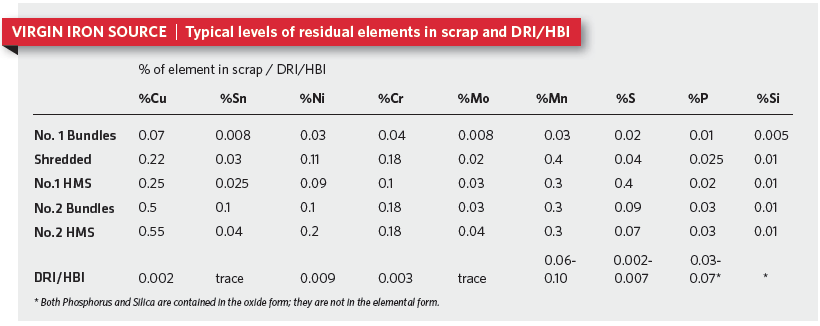

DRI – Direct Reduced Iron – is a premium quality, ore-based metallic raw material made by removing chemically-bound oxygen from iron oxide pellets or lump ores without melting. Extremely low levels of metallic residuals, such as copper, and high iron content DRI make DRI a highly effective diluent for other furnace charge materials and an efficient way to manage nitrogen content in liquid steel. It is used to make a broad range of steel products – all types of sheet including exposed auto body, extra deep drawing wire, special bar quality, forging bar, plate and seamless tube. The chemical and physical characteristics of DRI make it desirable for use in the electric arc furnace (EAF), blast furnace (BF) and basic oxygen furnace (BOF), as well as other melting and refining vessels.

DEVELOPMENT OF PRODUCT FORMS

The first modern direct reduction plants were built adjacent to the steel mills that used the DRI. Typically these plants were built to feed EAFs in areas where scrap supplies were limited. DRI was stored and bucket charged along with locally available scrap to make long products, such as reinforcing bar (rebar) and billets.

As the iron and steel industry became more aware of DRI and steelmaking technology continued to evolve, EAF operators began to realize that DRI could help them penetrate a market formerly reserved for traditional integrated steelmakers – flat products. Today all grades of steel can be produced in an EAF when DRI is included in the charge mix.

DRI became a globally traded product with the introduction of hot briquetted iron (HBI) and made available the benefits of DRI use to integrated steelmakers, who had previously considered DRI not suitable for use in the blast furnace. Today an increasing number of blast furnace operators are considering HBI for use in their blast furnaces on a regular basis to increase hot metal output when needed and to help limit CO2 emissions.

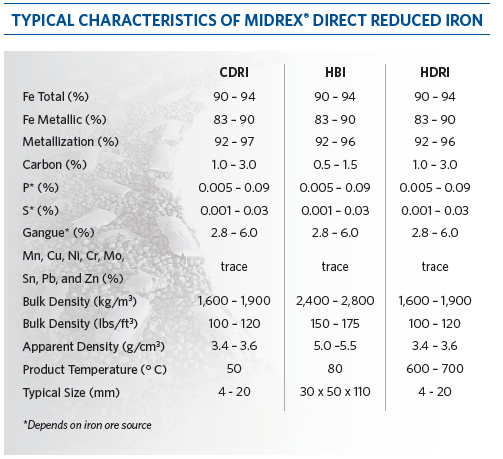

DRI PRODUCTS AND CHARACTERISTICS

New DRI product forms have been introduced to meet the changing needs of users and to address specific issues, such as long term storage, ocean carriage and size and density. Midrex has responded with direct reduction technology for hot discharge, transport and charging, as well as on demand and simultaneous discharge options.

DRI products are available in three forms: cold DRI (CDRI), hot DRI (HDRI) and hot briquetted iron (HBI).

Cold DRI (CDRI)

Most direct reduction plants built to date produce CDRI. After reduction, the DRI is cooled in the lower part of the reduction furnace to about 50° C. Typically CDRI is used in a nearby EAF shop as part of the primary metallic charge either in the scrap bucket or by continuous feeding. CDRI must be kept dry to prevent re-oxidation (rusting) and loss of metallization.

Hot Briquetted Iron (HBI)

HBI is the preferred DRI product for ocean carriage because it is much denser than CDRI, which reduces the re-oxidation rate and fines generation during handling and shipping. Its enhanced physical characteristics enable HBI to be stored and transported without special precautions under the International Maritime Organization (IMO) solid bulk cargo code. The size and density of HBI make it a desirable feed material for the EAF, BF and BOF.

The product characteristics of each direct reduction plant will be determined by the availability and quality of raw materials and reducing gas and in some cases will change in response to market conditions or other factors related to steelmaking. For example, some MIDREX® Direct Reduction Plants are operated at metallization rates of 92-93 percent while others produce continuously at 97 percent metallization to optimize a specific steelmaking practice.

Hot DRI (HDRI)

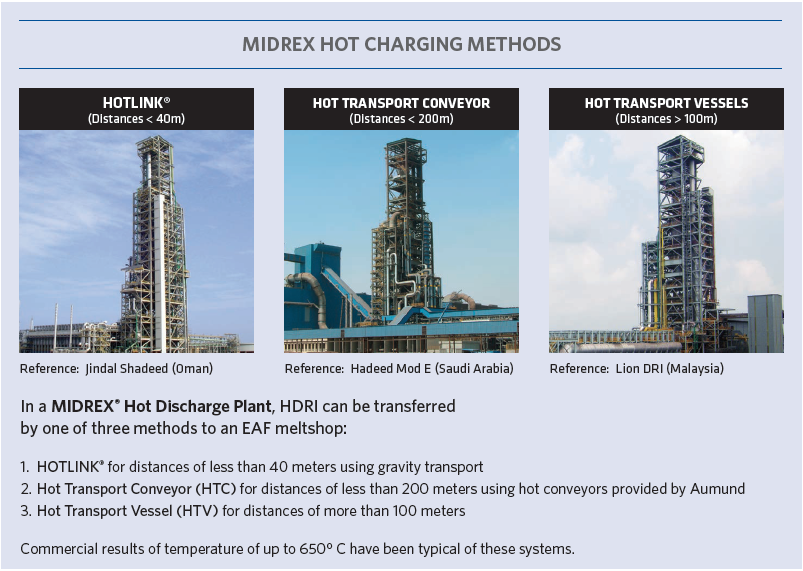

This form of DRI allows the steelmaker to take advantage of the sensible heat (thermal energy whose transfer to or from a substance results in a change of temperature) to increase productivity and/or reduce production costs. HDRI can be transported from a MIDREX® Shaft Furnace to a nearby steel mill at up to 650° C by one of three methods: enclosed and insulated conveyor, specially configured transport vessel or HOTLINK®, a system for direct feeding of HDRI to an EAF.

Remember that while some carbon is necessary in DRI, increasing the carbon content beyond what is needed to optimize the steel cycle time reduces the total iron present in the DRI and can actually increase tap-to-tap time in the EAF (for burning off the excess carbon or decarburization). In addition, the off-gas handling system must be sized to handle the large volumes of gases released during decarburization.

DRI USE IN IRON & STEEL PRODUCTION

The versatility of DRI can be best appreciated by its range of applications in iron and steelmaking. BF operators, who are under intense pressure to lower CO2 emissions while maintaining productivity levels, are looking to HBI as a solution.

Electric Arc Furnace (EAF)

EAF steelmaking and DRI have been closely associated for half a century. You might say they have grown up together – from producing low cost, carbon steel long products to making high quality flat products that meet the most exacting specifications.

Today DRI is still used primarily to make long products, such as reinforcing bars and light structural steel where scrap supplies are limited and costly to import. However, the chemical purity of DRI dilutes the copper and other undesirable constituents in the scrap charge when the EAF is called upon to make high quality flat products and low nitrogen steels.

DRI is ideally suited for use as either a replacement or supplement for scrap in the EAF. DRI provides EAF operators the flexibility to tailor their furnace charges to achieve the desired product quality at the lowest cost per ton of liquid steel.

This “metallics partnership” not only provides economic and operational flexibility, it brings even the highest steel specifications within reach of the EAF.

The benefits of DRI products go beyond their chemical properties. They can be charged either in scrap buckets or continuously fed to an EAF. When batch charged, the density of CDRI and HBI can eliminate the need for a second of third scrap charge, which results in lower energy losses, fewer interruptions of power on time, improved tap-to-tap time and increased productivity. Typically CDRI or HBI is used as up to 30 percent of the batch charge.

Continuous charging systems are used when CDRI, HDRI or HBI make up higher percentages of the total charge. Most commonly, a bucket of scrap is charged initially and then the DRI or HBI is continuously fed. This allows the furnace roof to remain closed and the power to stay on during most of the heat. Maintaining a consistent temperature improves bath heat transfer and speeds up metallurgical reactions.

HDRI can be transferred by either a hot transport conveyor system or in hot transport vessels to a nearby EAF at temperatures ≥ 600° C or it can be fed directly into an EAF from the reduction furnace by the HOTLINK® System.

A MIDREX® Plant equipped with any of the hot transport options can be designed to produce CDRI or HBI as alternate product streams when the melt shop does not need the HDRI. These plants can be switched from one DRI product to another quickly and without disrupting product flow or can product multiple products simultaneously.

There are two primary benefits of charging HDRI into an EAF: lower specific electricity consumption and increased productivity. Less energy input is required to heat HDRI to melting temperature, which results in a shorter overall melting cycle. The rule of thumb is that electricity consumption can be reduced about 20 kWh/t liquid steel for each 100° C increase in DRI charging temperature. Therefore, charging HDRI at over 600° C can yield electricity savings of 120 kWh/t or more.

A shorter overall melting cycle also reduces electrode and refractory consumption by at least 0.5 kg/t and 1.8 kg/t of liquid steel, respectively.

The increased productivity from HDRI charging is significant. Use of HDRI reduces the tap-to-tap time, resulting in a productivity increase of up to 20 percent versus charging DRI at ambient temperature.

BLAST FURNACE (BF)

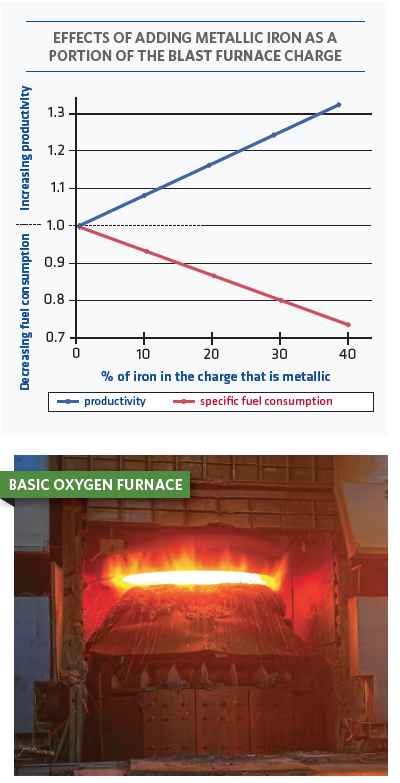

The overburden pressure of a large BF could crush CDRI; therefore, HBI is the best form of DRI for use in the BF due to its enhanced physical properties. It can be used to increase hot metal production and lower coke consumption as up to 30 percent of the BF charge with no significant equipment or process changes.

The addition of HBI increases hot metal production by boosting BF burden metallization … 8% more hot metal production when burden metallization is increased by 10%. This is highly desirable when:

- Hot metal availability is insufficient to meet demand

- Hot metal requirements are not matched to blast furnace output

- One blast furnace is offline for maintenance

HBI use in the BF has an environmental benefit as well. A 10% increase of BF burden metallization results in a 7% decrease of the coke rate, which in turn reduces CO2 emissions.

HBI has been used as part of the regular, routine operation of a commercial blast furnace in North America for over 25 years, as well as at other blast furnaces around the world. voestalpine AG will start-up a 2 million tons per year MIDREX® HBI Plant on the US Gulf Coast later this year. The HBI will be used in voestalpine’s own blast furnaces in Austria, making it the first plant primarily intended to produce HBI for BF use.

BASIC OXYGEN FURNACE (BOF)

HBI is the form of DRI best suited for use in the BOF because of its bulk density and physical strength. It is a preferred alternative to scrap in the initial cold furnace charge because:

- Residuals levels are low

- Bulk density is high

- Mass and heat balances are more accurate

- Steel chemistry is easier to control

HBI also performs well in the BOF as a portion of the cold charge, often as up to 1/3 of the total charge. Advantages of using HBI include:

- The cooling effect of HBI is approximately 10% greater than the cooling effect of scrap steel

- There is no increase in slopping, relative to using all scrap as the cold charge

- There is no sculling on the oxygen lance

- HBI can be used for low sulfur steels

- HBI has lower levels of copper and other undesirable metals than scrap steels

HBI can be charged to the BOF either from an overhead bin or by adding it to the charging box as up to 1/3 of the charge. HBI should be placed in the back of the box so that it will fall into the BOF last.

DRI OPERATIONAL VALUE & FLEXIBILITY

Through the years advances in production technology have continued to increase the value of DRI to iron and steelmakers and has earned the reputation of the steel industry’s most flexible charge material. As a result, the DRI industry has experienced phenomenal growth … from less than 1 million tons in 1970 to 75 million tons in 2014.

As the leading supplier of direct reduction technology, Midrex has made DRI more accessible, more economical to produce and more profitable to use through market-driven innovations and improvements.

Examples include:

- Hot briquetting for safer shipping and easier handling

- Oxide coating to increase DRI production

- Combination plants capable of simultaneous, on demand discharge of various DRI products

- Hot DRI transport and charging to increase EAF productivity, reduce cost/ton of liquid steel

- Flexible production rates to accommodate changing market conditions

- Reductant sources options when natural gas is not available or affordable

- Ability to operate effectively with any commercially available iron oxide pellets, lump ores and blends of the two

Glossary of Direct Reduction Terms

These terms are commonly used when discussing direct reduction products and the methods/procedures for handling, shipping, and storing these products.

Carbon Content (%): total carbon present in DRI as a percentage of total weight of DRI. Carbon in DRI can be both in free form and as cementite (Fe3C).

Cementite (also known as Iron Carbide): a hard, brittle compound of iron and carbon (93.3% iron and 6.67% carbon by weight).

Cold DRI (CDRI): product that is cooled in the lower part of the reduction furnace to approximately 50° C prior to discharge. Most DRI plants built to-date produce CDRI.

Degree of Reduction (%): amount of iron-bound oxygen removed during the reduction process.

Direct Reduced Iron Feedstock:

Pellets (DR-grade): iron ore concentrate that has been formed into round balls (agglomerated), fired, and indurate at a temperature of about 1360° to 1400° C. Total iron content is typically 66 to 67%, and particle size ranges from 9 to 16 mm diameter.

Lump: natural iron ore chunks as mined, having a particle size between 9 to 25 mm and a total iron content of 63 to 65%.

Fines: natural iron ore particles as mined or as produced during the crushing of large particles of natural, coarser particles. Fines are classified as pelletizing fines or sintering fines. Pelletizing fines have a particle size between 0 and 12 mm and are used in fluidized bed direct reduction processes.

Direct Reduced Iron (DRI): the product of iron oxide pellets, lump ores or fines that have been reduced (i.e., oxygen removed) in a direct reduction process at temperatures in excess of 900° C, thereby increasing the percentage (by weight) of total iron in the reduced product. All other oxides in the ore remain in their natural state.

DRI products include:

Cold DRI (CDRI): product that is cooled in the lower part of the reduction furnace to approximately 50° C prior to discharge. Most DRI plants built to-date produce CDRI.

Hot DRI (HDRI): product that is discharge from the reduction furnace without cooling and transported to a nearby steel shop by an insulated conveyor or transport vessel or directly charged by gravity flow in the case of MIDREX HOTLINK®.

Hot Briquetted Iron (HBI): product that is discharged from the reduction furnace without cooling and compressed into dense (≥ 5 g/cm3), pillow-shaped briquettes (30x50x110 mm) at a temperature ≥ 650° C without the use of a binder material.

The International Maritime Organization (IMO) identifies direct reduced iron as:

Direct Reduced Iron (A) Briquettes, hot-moulded: IMO classification for Hot Briquetted Iron (HBI).

Direct Reduced Iron (B) Lumps, pellets and cold-moulded briquettes: IMO classification for pellet and lump DRI.

Direct Reduced Iron (C) By-product fines: IMO classification for DRI fines and other byproducts from the production and handling of DRI (A) and (B).

DRI Fines: the result of physical degradation of the particle size distribution of pellets, lumps, and fines during the reduction process caused by the action of rubbing, crepitation, shear stresses, etc. Fines also can be generated during the processing, handling and screening of DRI (A) and DRI (B) prior to use in iron and steel production processes. Normal size distribution depends on the feedstock and can range from 0 to 12 mm. Metallic iron content is in the range of 1.0 to 75.0% by weight.

Gangue: non-Fe components of iron ore that are retained in DRI products (e.g., SiO2, Al2O3, CaO, MgO, MnO, TiO2, P2O5 and S). Gangue content of DRI typically is 3-5%.

Gangue Basicity: weight ratio of basic (CaO and MgO) to acid (SiO2 and Al2O3) gangue components in DRI products.

IMSBC Code: International Maritime Solid Bulk Cargoes Code, as published by the International Maritime Organization (IMO), which contains provisions governing the carriage of solid bulk cargoes and the carriage in bulk of dangerous goods in solid form.

Iron Yield (%): total iron present in DRI that is recovered as liquid steel by melting.

Liquid Steel (or Melting) Yield (%): total DRI weight that is recovered as liquid steel by melting.

Metallic Iron Content (%): total DRI weight present as metallic iron exclusive of iron-bound oxygen (FeO).

Better understood in steelmaking as a direct function of the total iron percentage of the DRI feedstock and the metallization percentage of the DRI product.

Metallization (%): total iron present in DRI as metallic iron. Commonly used by the direct reduction industry (in relation to energy consumption) to define the efficiency of the direct reduction process.

Phosphorus Content (%): total phosphorus present as a percentage of total DRI weight, typically as P2O5.

Pre-reduced Iron: partially reduced iron product in pellet, lump or briquette form produced from iron ore without melting. Metallization is less than 85%, and it is not suitable for steelmaking.

Residual Elements: non-ferrous metals that are volatized or remain in the liquid steel bath upon melting. The most common residual elements in steelmaking are Cu, Ni, Cr, Sn, Mo, Pb, V and Zn. Total content of residual elements in DRI products is less than 0.02%.

Sponge Iron: term used in the early days of the direct reduction industry to describe non-briquetted DRI and pre-reduced iron.

Total Iron Content (%): total iron present in DRI products (metallic iron + oxygen-bound iron) as a percentage of total DRI weight.

Tramp Elements: term used for residual elements plus sulfur and phosphorus.