Press Release | Midrex - Company

MIDREX® Process – Rock Solid at 50

May 28, 2019 Download

Celebration of First MIDREX Plant

CHARLOTTE, North Carolina, USA (May 28, 2019) – The first plant based on the MIDREX Direct Reduction Process, which transforms iron oxide into a high-quality iron material for use in making steel, began production 50 years ago – on May 17, 1969, in Portland, Oregon, USA.

The MIDREX Process is the world’s most productive technology for the direct reduction of iron ore. With MIDREX Plants operating in 21 countries, Midrex Technologies, Inc. is widely credited for developing and expanding the global direct reduced iron (DRI) market through its advocacy for using DRI products in combination with scrap in the electric arc furnace (EAF). And the numbers prove it, with MIDREX Plants producing more than 60% of the world’s DRI since 1987, helping overall production to grow more than 25% since the beginning of 2017.

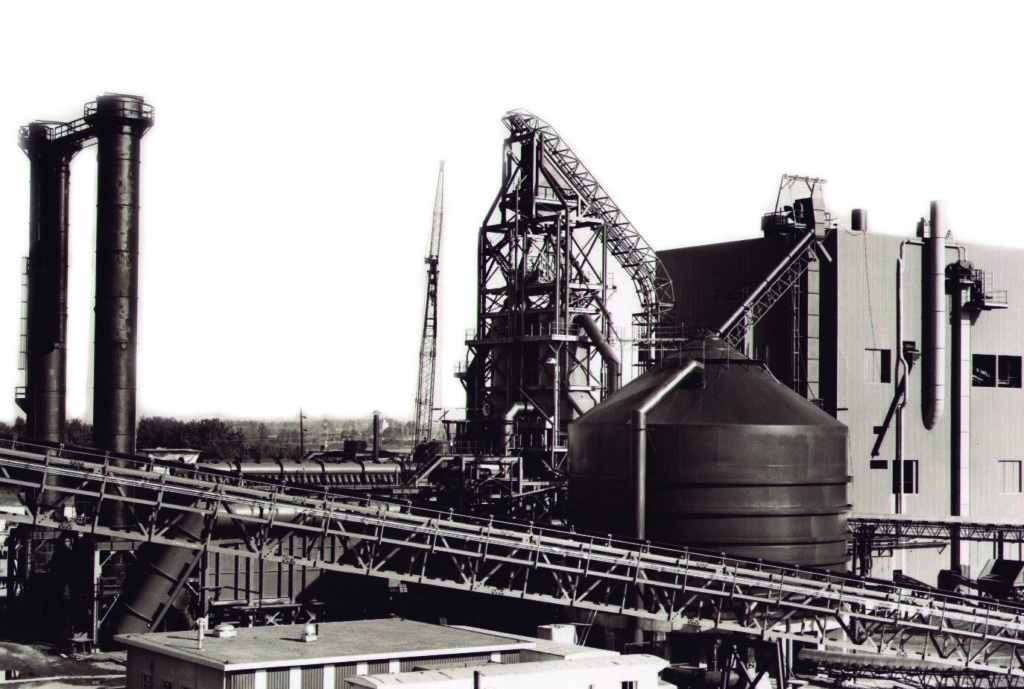

1969: The first MIDREX Plant at former Oregon Steel Mills in Portland, Oregon, USA

Midrex employees past and present gathered as one team on May 17th to celebrate the 50th anniversary of the first MIDREX Direct Reduction Plant and to honor three of the engineers who helped develop the foundation of the technology and put the Portland plant into operation: Winston L. Tennies, who also is a past President & CEO of Midrex Technologies, Inc., David C. Meissner, and Bruce G. Kelley.

“The early Midrex pioneers set a standard of excellence, which guides and inspires us today,” said Stephen C. Montague, current President & CEO of Midrex Technologies, Inc. “We continuously improve the technology to optimize performance of MIDREX Plants, as well as to become more environmentally friendly. We also give back through skills training and employment opportunities where our plants are located,” he said.

“Our company is about pulling people together to make a difference, whether in the office, for the environment, or in the community. We are a team dedicated to serving others,” said Montague.

About Midrex

Midrex Technologies, Inc. is the world leader for direct reduction ironmaking technology based in Charlotte, North Carolina, USA. It operates a center of excellence for ferrous and non-ferrous reduction technology development in nearby Pineville, NC. Each year, MIDREX Plants produce more than 60% of the world’s DRI in its three forms: cold DRI (CDRI), hot DRI (HDRI), and hot briquetted iron (HBI).

The MIDREX Process had its beginning in Toledo, Ohio, USA, in the Surface Combustion Division of Midland-Ross Corporation. Donald Beggs, Surface Combustion’s head of research, was intrigued by the idea of reforming natural gas to produce a high-quality synthesis gas that could reduce oxide pellets (by removing the oxygen) without melting them. Beggs and Jack Scarlett, another member of the Surface Combustion research group, developed and filed a patent application for a process flowsheet, and a pilot plant was built. The DRI produced by the pilot plant was supplied to Oregon Steel Mills, which operated an EAF in a scrap-deficient area. The steel mill set a new production record when using the DRI, and an agreement was reached to build a full-scale commercial prototype plant in Portland, Oregon, USA.

The cumulative production of DRI by MIDREX Plants reached 1 billion metric tons in June 2018. It took 38 years to produce the first 500 million tons but only 11 to achieve the second 500 million tons. At the current production rate of 60 million t/y and with sufficient capacity under construction to push the rate to 75 million tons/year by 2020, it could take less than 13 years to produce the second billion tons of DRI.

For more information about the products and services of Midrex, visit: https://www.midrex.com.