Direct Reduction Technology

The MIDREX® Process – The world’s most reliable and productive direct reduction ironmaking technology.

Learn More

The MIDREX® Process – The world’s most reliable and productive direct reduction ironmaking technology.

Learn More

Midrex has a unique blend of existing and new technologies that produce iron with the lowest CO2 emissions in the world.

Learn More

Midrex Technologies, Inc. recognizes the importance of protecting the environment and conserving natural resources.

Learn MoreReflecting on decades shaping Direct From Midrex’s editorial journey.

Learn MoreMidrex achieves dual ISO certifications with zero reported nonconformances.

Global MIDREX community gathers annually to share knowledge and innovation.

ONE TEAM, COMMITTED TO GROWTH & RESPONSIBILITY Commemorating the 120-year anniversary of Kobe Steel Since the founding of the Kobe Steel Works, Ltd. in 1911, Kobe Steel Ltd. (KSL) and...

Global DRI hit 140.8 Mt in 2024, with MIDREX® leading.

CHARLOTTE, NC, USA (October 20, 2025) – Eurasian Resources Group (ERG), a global metals and mining company, has signed a strategic contract with a consortium of Primetals Technologies and Midrex Technologies, Inc. (Midrex). The agreement covers detailed engineering, supply of key process equipment, and a range of services for the construction of a hot briquetted iron (HBI) plant in Rudny, Kazakhstan. This marks the next major milestone in the partnership, following the completion of pre-engineering and basic engineering packages.

The MIDREX® Flex plant will be one of the largest next-generation metallurgy facilities in Central Asia. Producing HBI with a metallization degree of at least 93.5 percent and an iron content of approx. 90 percent will enable Kazakhstan to enter the global HBI market with a new, competitive product. The MIDREX Flex plant is designed for a seamless transition to hydrogen utilization when it becomes commercially viable.

Read the full press releaseWe are committed to providing the best-proven method for decarbonization in the iron and steel industry, direct reduction.

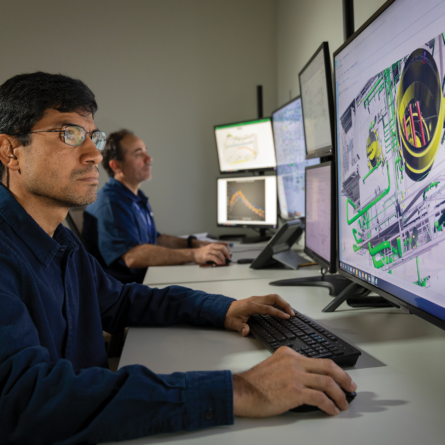

Watch VideoAt Midrex, you will do work that matters, with people who believe you matter. The work won’t be easy. But it will be worth it, as we work together to transform our industry.

Career Opportunities