Increasing Carbon Flexibility in MIDREX® DRI Products – Adjustable to 4.5%, Excellent Temperature Retention with MIDREX ACT™

Adjustable to 4.5%, Excellent Temperature Retention with MIDREX ACT™

Worldwide, there are approximately 70 MIDREX® Plants producing Direct Reduced Iron (DRI) products: cold direct reduced iron (CDRI), hot direct reduced iron (HDRI) and hot briquetted iron (HBI), or a combination of these forms of DRI (Figure 1). Over the nearly five decades the MIDREX® Direct Reduction Process has been in operation, product carbon levels have varied based on plant location and product use. In 2016, MIDREX® Plants produced more than 47 million tons of DRI products with carbon levels of approximately 0.5% to 3%, controllable to meet the requirements of individual plant operators.

Recently, Midrex Technologies, Inc. has created a new flexible technology that can increase the carbon content of DRI produced in a MIDREX Plant up to 4.5% while maintaining the discharge temperature. This patent pending innovative technology is called ACT™, which stands for Adjustable Carbon Technology. MIDREX ACT™ allows MIDREX® Plants to produce the widest range of carbon in DRI products and can be easily adjusted during operation. The technology can be retrofitted to existing plants or integrated in the design of a new plants to provide Midrex customers the flexibility to produce a higher carbon DRI and HBI.

FIGURE 1.

DRI Product Forms

MAKING CARBON THE MIDREX WAY

In the MIDREX® Shaft Furnace, carbon is added to DRI in three places:

- The reduction zone – In the MIDREX® Process, the main purpose of the reduction zone is to metallize the iron to the desired product metallization using reductants CO and H2 produced by the MIDREX® Reformer. However, some carbon is added in the reduction zone derived from CH4 and CO. Carbon from CH4 is endothermic (i.e., consume heat), while carbon from CO is exothermic (i.e., liberates heat).

- The transition zone – A controlled flow of transition zone natural gas is added, which is the main method of adding and controlling the amount of carbon in MIDREX® DRI Products. The natural gas feedstock to MIDREX® Plants contains hydrocarbons, mostly methane, and using methane as an example, the carbon comes by:

These carbon-forming reactions are endothermic and cool the DRI, this is desirable for plants producing CDRI but not necessarily so for plants producing HDRI or HBI.

These carbon-forming reactions are endothermic and cool the DRI, this is desirable for plants producing CDRI but not necessarily so for plants producing HDRI or HBI. - The cooling zone – MIDREX® Plants that have a cold discharge furnace use cooling gas to cool the DRI. The cooling gas contains hydrocarbons and carbon is added in a similar manner as in the transition zone.

DEVELOPMENT OF MIDREX ACT™

To meet market demands for a more flexible DRI product, Midrex Research and Technology Development was challenged to develop a new technology to add carbon without cooling the DRI. The technology had to be flexible (carbon easily adjustable during plant operation) and capable of being added to the MIDREX® Process to permit the retrofitting of existing plants, With the MIDREX ACT™, carbon monoxide (CO), made in the MIDREX Reformer, is added to the transition zone in the form of a CO-rich gas stream. The CO contacts the DRI bed and the resulting exothermic reactions provide extra energy:

Transition zone natural gas is added along with the CO-rich stream, using the CO-generated energy to provide the energy to produce additional carbon without sacrificing temperature:

By adjusting the amount of CO added to the transition zone, the plant operator can adjust the amount of energy added to DRI products. Adjusting the natural gas addition will control the carbon content of the DRI. Using these simple principles, this technology allows for independent control of the temperature increase and the amount of carbon added.

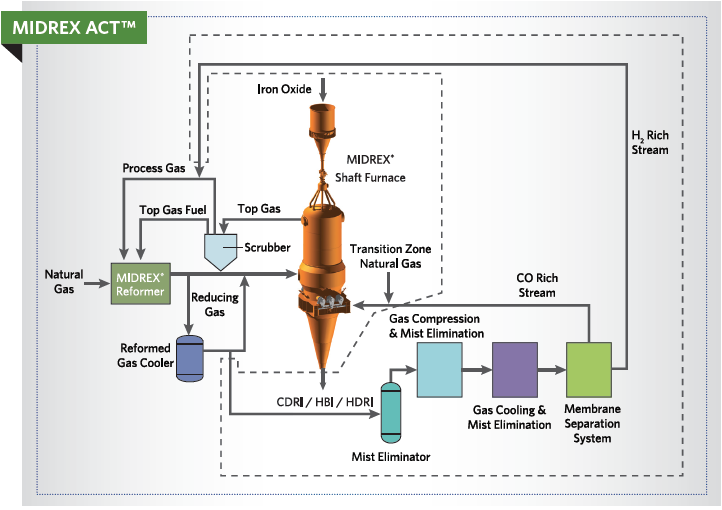

FIGURE 3.

Simplified MIDREX ACT™ Flowsheet

MIDREX ACT™ AT A GLANCE

• Can be used in every type of MIDREX® Plant (CDRI, HDRI, HBI or a combination)

• Allows amount of carbon in DRI to be adjusted up or down

• Carbon can be added without cooling the DRI

• 85-90% of the carbon in MIDREX® DRI Products will be in the form of iron carbide (Fe3C)

• Can be retrofitted into existing MIDREX® Plants, as well as included in new MIDREX® Plants

• Can be turned on and off to suit the desired carbon level without disrupting plant operation (i.e., MIDREX® Process can operate with or without it).

MIDREX ACT™ DESIGN FEATURES

The MIDREX ACT™ starts by diverting a portion of the reformed gas, which is rich in H2 and CO to the reformed gas cooler. All equipment used is well-proven and reliable. A simplified flow-sheet is shown in Figure 3.

Reformed Gas Cooler

All new MIDREX® Plants (and most existing ones) have a reformed gas cooler, which is used to control bustle gas temperature during plant start-up and occasionally during normal operation. There, a relatively small stream (typically about 10% of the reformed gas flow) of cooled reformed gas is diverted to the MIDREX ACT™.

Mist Elimination

The cooled reformed gas is then sent to a mist eliminator, which is similar in design to ones already used in MIDREX® Plants, to remove excessive water and protect subsequent equipment.

Gas Compression

The gas is then compressed to approximately 14 barg. This pressure is needed for the downstream membrane unit.

Gas Cooling

The gas from the compressor is hotter than needed for the downstream membrane unit, so it is cooled by a syngas aftercooler and the mist is removed by a mist eliminator. This equipment is similar in design to that which Midrex supplies in current new plants.

Membrane Separation

The gas, having been suitably compressed and cooled, enters the membrane unit. This technology, which is used in gas separation industries, employs a pressure difference to selectively allow some of the gas components in the feed stream to permeate across a membrane, separating the feed into two product streams. In this case, a CO-rich stream and a H2-rich stream are produced. The CO-rich stream is sent to the transition zone, where the exothermic reactions generate heat (and some carbon deposition) and the endothermic reactions deposit carbon. The H2-rich stream (i.e., the low-pressure stream from the membrane unit) is recycled to the discharge of the process gas compressors. The gas entering the membranes is cleaned and suitably conditioned within the membrane system, the features of which have been tailored for the MIDREX® Process.

Controls and Logic

The amount of carbon added to the MIDREX® DRI Products is adjusted by the flowrate of gas to the membrane unit (affecting mostly temperature) and the flowrate of transition zone natural gas (affecting mostly carburization), which provides operators an independent control loop for carbon and temperature. The necessary engineering was performed for piping, controls, instrumentation, gas composition measurements, isolation and control logic for normal operation, start-up, shut-down and isolation of the MIDREX ACT™.

Utilities

The MIDREX ACT™ has the following utilities requirements:

- ELECTRICITY – Electrical consumption for the MIDREX® Plant will increase approximately 20 kWh/ton of DRI due mainly to the compressor and the electric heater in the membrane unit.

- COOLING WATER – Machinery cooling water is needed for compressor cooling and the syngas aftercooler.

- NITROGEN – A small amount of nitrogen is needed intermitently for system purging.

- INSTRUMENT AIR – A small amount of instrument air is needed for control valves.

CONCLUSIONS

The MIDREX ACT™ increases the product flexibility of existing or new MIDREX® Plants by providing an independent means to increase the carbon level of the DRI products or to increase the discharge temperature at a given carbon level. For applications where higher carbon is desired, the amount of carbon added is controllable and the DRI discharge temperature is maintained; with this technology, MIDREX® Plants will have a wide range of carbon amounts available to them – from 0.5% up to 4.5%.

With the MIDREX ACT™, a MIDREX® Plant will have the ability to:

- Produce CDRI with higher carbon content.

- Produce HDRI with either higher carbon or at higher temperature or both.

- Produce HBI with higher carbon content without detrimental loss of temperature at the briquetting machine or increasing briquetting temperature at a given carbon content.

- Merchant plants (CDRI and HBI) can tailor their product chemistry and produce a value-added product to the specifications of their end users

- Chose to operate with MIDREX ACT™ when higher carbon levels are desired or to operate without MIDREX ACT™ when lower carbon levels are desired.

MIDREX ACT™ is designed for retrofitting into existing plants, and the equipment used in the technology is well proven in actual operation. The design is of the same robust nature as all MIDREX® Technology solutions. There will be some additional OPEX, mainly due to increased electrical consumption.