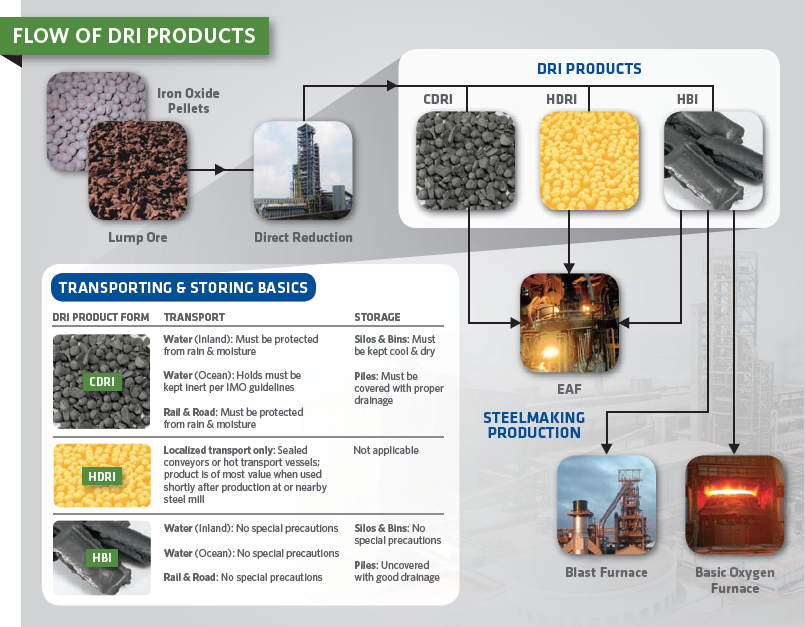

The need for a dependable and clean source of iron will continue to increase as steelmaking grows and expands globally. Regardless of the steelmaking route, there is a form of direct reduced iron (DRI) for every application.

DRI is a premium ore-based metallic (OBM) raw material made by removing chemically-bound oxygen from iron oxide pellets and lump ores without melting. DRI is high in iron content and low in copper and other undesirable metals, tramp elements, and nitrogen content. It is used to make a broad range of steel products…all types of steel up to and including exposed auto body, extra deep drawing quality, fine wire, special bar quality, forging bar quality, plate and seamless tubes. Its physical and chemical characteristics make it desirable for use in the electric arc furnace (EAF), blast furnace (BF), and basic oxygen furnace (BOF).