The Strength Within: Revealing the Mechanical Properties of DRI

Midrex, Kobe Steel Shaft Furnace Simulation Captures Industrial-Grade DRI Data

Introduction

Understanding the relationship between reducing gas compositions and the mechanical properties of direct reduced iron (DRI), especially swelling behavior and strength, is an area of research of growing importance in the quest to decarburize steelmaking. A promising decarburization pathway is to replace some or all of the energy from fossil fuels with green hydrogen (H2) to produce DRI in a MIDREX® Shaft Furnace.

Two studies performed in 2017 and 2022 (M. Mizutani et al. in 20171 and Z. Zhao et al. in 20222) indicated that there is less possibility of swelling and disintegration when DRI is produced under a pure hydrogen (H2) atmosphere than with an H2 and carbon monoxide (CO) gas composition. However, unlike in a real shaft furnace, where the counter current flow of the reducing gas against the solid flow results in a non-isothermal and non-constant gas composition condition, these studies were carried out under isothermal and constant gas composition conditions.

To better represent the actual shaft furnace and the mechanical properties of DRI produced therein, Midrex Technologies and Kobe Steel developed a test procedure called Shaft Furnace Simulated Condition (SFSC). SFSC simulates the reducing condition in a MIDREX Plant using natural gas as reductant and compares the obtained mechanical properties with those obtained from the conventional isothermal test method and a commercial plant.

Background

Corem, a research institute specialized in the area of mining and mineral processing, developed a non-isothermal reduction test called R180, which compared the microstructure of the reduced pellets with those obtained from the conventional isothermal test (R90) specified by ISO 112583. The Corem test also compared the porosity, strength, and microstructure of the DRI produced by the R180 procedure with industrial DRI. They found the properties to be similar; however, it is not clear how many pellet brands were tested or whether all of them had similar physical properties as the industrial ones.

Shaft Furnace Simulated Condition (SFSC)

The purpose of SFSC is to reproduce the metallization and mechanical properties of industrial DRI for most of the recognized oxide pellet brands in a specially-designed bench-scale reduction furnace (see Figure 1).

FIGURE 1.

Schematic of SFSC furnace

SFSC Furnace Setup

For each test, 14 pieces of oxide pellets (approximately 50 grams) are placed in a hand-made sample holder so the location of each sample can be tracked during the reduction test. The sample holder is suspended inside a 75 mm (dia.) ceramic retort from an electronic balance. This setup enables the monitoring of volume change before and after each test and weight change of the sample during the test. Both the upper and lower end of the retort are tightly sealed by water-cooled flanges with O-rings. The reducing gas consists of H2, CO, and CO2, and is mixed well before it is introduced into the retort. The exhaust gas from the top of the retort is combusted by a burner to ensure operator safety.

SFSC Test Procedure

Before each reduction test, the pieces of oxide pellets are heated to the initial reduction temperature under a nitrogen (N2) atmosphere. The heat pattern simulates that of an actual industrial plant.

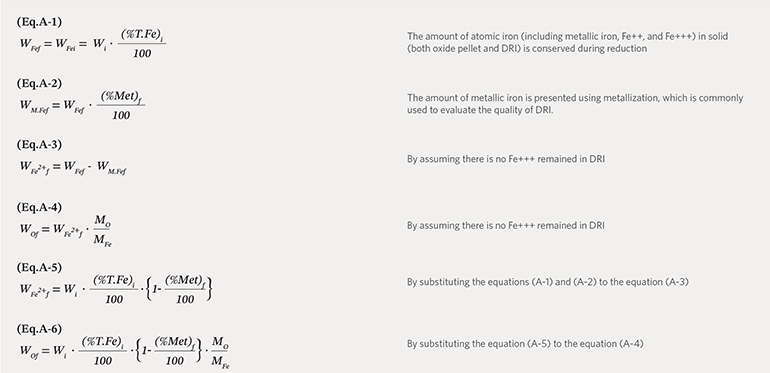

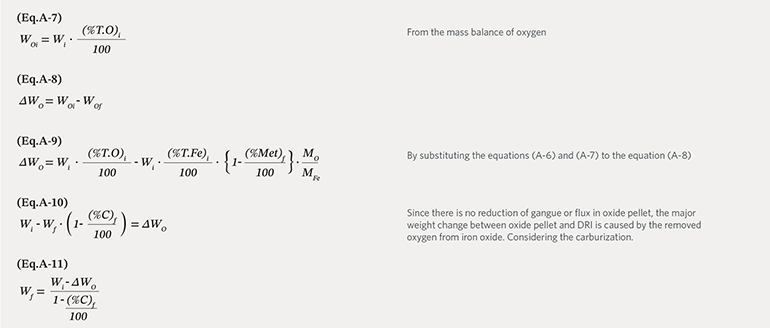

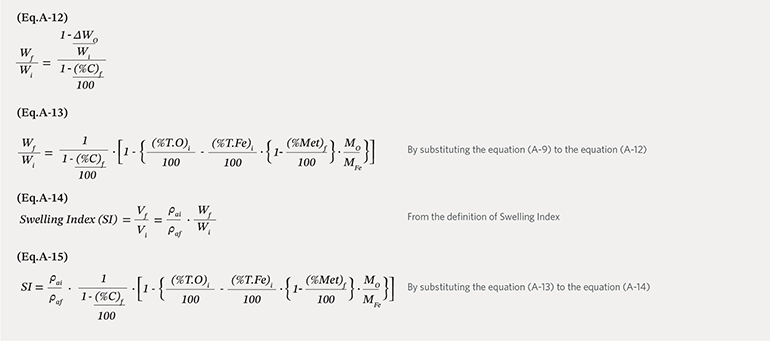

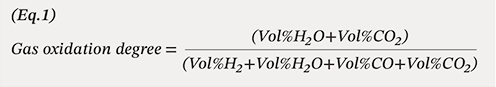

The SFSC test conditions are shown in Table 1. At the beginning of the test program, the gas composition is set to the same Gas Oxidation Degree (GOD*) as the representative composition of the exhaust gas from the shaft furnace in a MIDREX Plant. The GOD decreases as the test proceeds and eventually reaches the same value as the bustle gas, which in an industrial plant comes from a MIDREX Reformer and is introduced to the shaft furnace. The transition of GOD between the bustle gas and the exhaust gas is simulated by Computer Fluid Dynamics (CFD) technology and applied to the SFSC. Gas composition is changed 17 times (every 10 minutes) during the 180 minutes of the test to better simulate the real reduction condition. In comparison, the R180 procedure developed by Corem only has three steps of gas composition change.

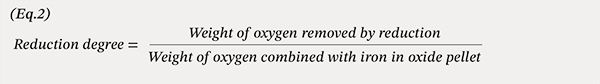

*GOD is defined by Eq.1. Gas with a lower GOD is a better reductant.

TABLE 1.

SFSC Test Conditions

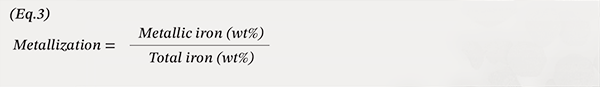

Three initial temperature setpoints were examined to reproduce the microstructure of industrial DRI. The transitions of microstructure in an industrial oxide pellet (oxide pellet A in Table 2) with varied initial temperature are shown in Figure 2. Both porous and dense microstructure can be seen at approximately 30% and 100% of reduction degree (RD**) while the raw material shows only the dense one. As can be seen in Figure 2, as the initial reduction temperature increases from Case I, Case II, and Case III, the proportion of porous particles of the partially reduced DRI (30% RD) increases as well. The order of porous particle proportion of the DRI at 100% RD follows that of the 30% RD. High initial reduction temperature leads to high porosity DRI. The conclusion was that the microstructure shown in Figure 2F is the closest to that of industrial DRI (Figure 2H). Consequently, Case II, with the medium initial reduction temperature, was determined to be the best setup for the reproduction of the microstructure of industrial DRI. Therefore, In the rest of this article, SFSC will refer to Case II.

** RD is defined by Eq.2, which represents the reduction progress besides metallization***. The higher the reduction degree, the farther the reduction progresses.

***Metallization is defined by Eq.3.

FIGURE 2.

CT-Photos of oxide pellet A and reduced samples made from oxide pellet A:

- A – Oxide pellet A (common to Cases I, II, & III)

- B – Sample with approximately 30% of RD, reduced under the modified SFSC with lower initial temperature

- C – Sample with approximately 30% of RD, reduced under the SFSC

- D – Sample with approximately 30% of RD, reduced under the modified SFSC with higher initial temperature

- E – Sample with approximately 100% of RD, reduced under the modified SFSC with lower initial temperature

- F – Sample with approximately 100% of RD, reduced under the SFSC

- G – Sample with approximately 100% of RD, reduced under the modified SFSC with higher initial temperature

- H – Industrial DRI made from Oxide Pellet A

Raw materials and other conducted tests

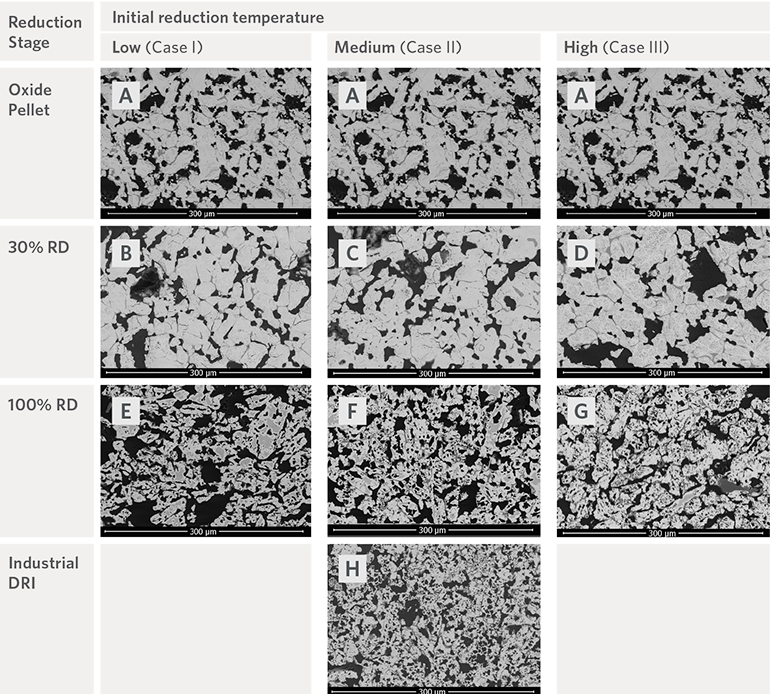

To better predict the mechanical properties of industrially produced DRI in a laboratory test, the test procedures must be applicable to a wide selection of oxide pellet brands. Therefore, 10 brands of commercial oxide pellets were used in the SFSC study. The major characteristics of these oxide pellets are shown in Table 2. The pellets also were subjected to a Basket Test in an industrial DR plant as part of the reduction study. In a Basket Test, soft or hard baskets filled with oxide pellets are fed to the top of a shaft furnace and collected from the bottom of the shaft after reduction. In this article, the DRI obtained from a Basket Test is called Industrial DRI.

TABLE 2.

Characteristics of Oxide Pellets Tested

Three of the 10 brands of commercial oxide pellets (designated A, B, and C) also were examined in an extended R90 test, where the temperature and gas composition were the same as specified by ISO 11258 at isothermal condition, except the test duration was extended from 90 minutes to 180 minutes. The extended R90 was performed to allow the oxide pellets to undergo full reduction3. The same test furnace as developed for SFSC was used for the extended R90 test.

Further tests (called Stop Tests) were performed on oxide pellet A to examine the transition of the mechanical properties of the oxide pellets at varying Reduction Degrees, and 14 samples were used in each Stop Test at every target Reduction Degree. Both SFSC and the extended R90 conditions were applied for the Stop Tests. Table 3 summarizes the various test characteristics.

TABLE 3.

Summary of Test Characteristics

Reduction

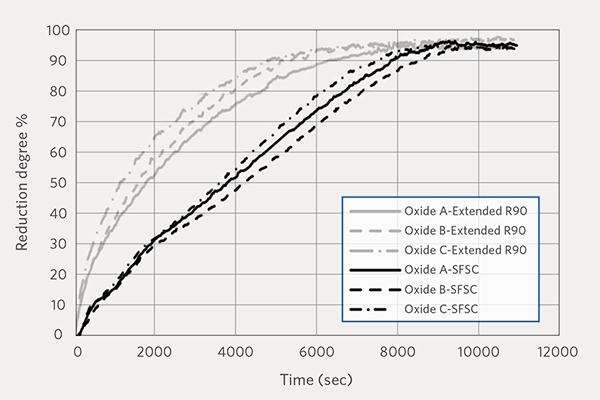

The reduction curves (relationships between the Reduction Degree and the elapsed time) obtained from the extended R90 and SFSC are shown in Figure 3. For each oxide pellet brand, the reduction rate in the extended R90 is faster than that in SFSC while the final Reduction Degrees are in same range.

FIGURE 3.

The reduction curve (relationship between the Reduction Degree and the elapsed time) in the

extended R90 and SFSC laboratory test for three oxide pellet brands

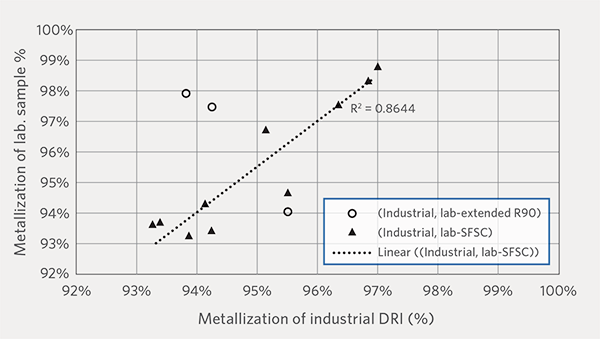

The metallization results of the same oxide brand obtained from the Basket Test and the laboratory test are shown in Figure 4. The DRI in the extended R90 tests exhibited an opposite metallization trend relative to the industrial DRI. The pellets that showed the highest metallization in the extended R90 test produced the lowest metallization when they were subjected to the Basket Test. On the other hand, the metallization results obtained from SFSC showed good agreement with that of the industrial DRI. Therefore, it can be said that the SFSC is similar to the reducing condition in an actual DR plant.

FIGURE 4.

Comparison of metallization between each laboratory test and an industrial test

(Metallization is defined as the ratio of the mass percentage of metallic Fe to the mass percentage of total Fe in DRI. For the laboratory tests, the mass percentage of metallic Fe was measured by Kobe Steel, Ltd. using the Bromine methanol titration method specified by ISO 5416. For an industrial test, the mass percentage of metallic Fe was measured by Midrex using the Ferric chloride titration method specified by ISO 16878.)

Mechanical properties

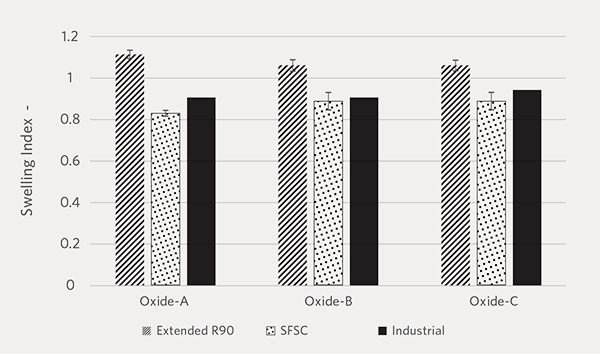

Fourteen samples were collected from each laboratory test (the extended R90 or SFSC) and their weight and volume were measured. The Swelling Index, or the volume ratio of each reduced sample relative to its initial state, was calculated. A Swelling Index greater than 1 implies that the volume of the reduced sample is higher than that of the raw oxide pellet.

Swelling Index obtained from the extended R90, SFSC, and Basket Test are compared in Figure 5. Only for the industrial sample, the Swelling Index was calculated, as described in the Appendix since it is impossible to track a single oxide pellet during the entire reduction. For extended R90 and SFSC, the volumes before and after reduction were directly measured to calculate Swelling Index. For each oxide pellet brand, the Swelling Index of the extended R90 is the highest and different from those of SFSC and industrial DRI. This means the oxide pellets expanded significantly, in an unnatural way. While the Swelling Index of SFSC is slightly lower than the industrial DRI, the reproduction of the microstructure of industrial DRI may have resulted in similar swelling behavior to that of industrial DRI.

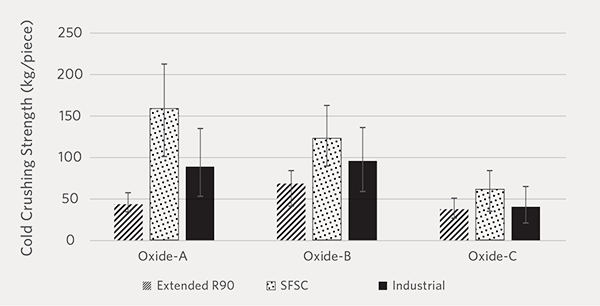

FIGURE 5.

Comparison of Swelling Index among two laboratory tests and an industrial DRI test.

Cold Crushing Strength (as specified by ISO 4700) of the sample obtained from the extended R90, SFSC, and Basket Test is compared in Figure 6. For each oxide pellet brand, the Cold Crushing Strength of the extended R90 is the lowest and SFSC is the highest. The industrial DRI is between the extended R90 and SFSC. In the extended R90, the extreme volume expansion may have resulted in the lower strength than that of the industrial one. For SFSC, the strength was higher than the industrial DRI even though the volume change during reduction was similar. One explanation is the sintering of iron particles in DRI after the completion of reduction. In the industrial plant, DRI is carburized and cooled just after the completion of reduction. So, there is little sintering of DRI iron particles in the shaft furnace. However, in SFSC testing, the fully reduced DRI was held for an additional 20-30 minutes at 850 °C in the furnace shown in Figure 1 after reduction was completed (see Figure 3). The iron particles in the DRI may sinter during this period, which may lead to the enhancement of strength and higher Cold Crushing Strength than that of industrial DRI. Therefore, shortening the test time of SFSC could better reproduce “true” Cold Crushing Strength of industrial DRI.

FIGURE 6.

Comparison of Cold Crushing Strength among two laboratory tests and an industrial test

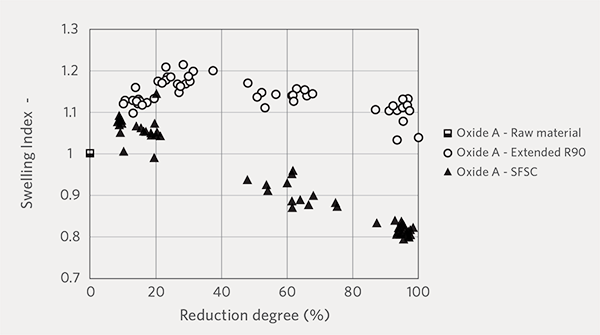

The relationship between Swelling Index and Reduction Degree obtained from the Stop Test on oxide A is shown in Figure 7. Before the reduction begins, the Swelling Index of raw material is 1. Once reduction occurs, the sample expands until its volume reaches the maximum at a certain reduction degree, and then it shrinks. For extended R90 testing, the Swelling Index reaches its peak (1.2) at 30% Reduction Degree and lowers slightly after 30%. On the other hand, in SFSC, the Swelling Index reaches its peak (1.1) at 10% of Reduction Degree and then decreases more sharply than in the extended R90.

FIGURE 7.

Transition of Swelling Index of oxide A both in the extended R90 and SFSC testing

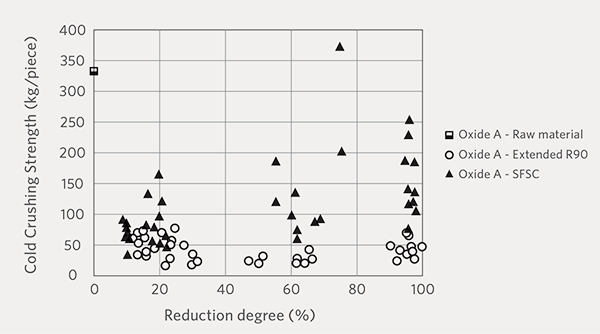

The relationship between Cold Crushing Strength and Reduction Degree is shown in Figure 8. Before reduction tests, the average Cold Crushing Strength is higher than 300 kgf/piece, which is within the normal range for oxide pellets. Once reduction occurs, the strength immediately drops to approximately 50 kgf/piece. In extended R90 testing, once the strength drop occurs, the strength remains unchanged until the end of the reduction test. On the other hand, recovery of strength in accordance with the progress of reduction was observed in SFSC testing. Consequently, the Cold Crushing Strength of DRI obtained from SFSC is higher than that obtained in the extended R90 test.

FIGURE 8.

Transition of Cold Crushing Strength of oxide A both in the extended R90 and SFSC testing

Conclusions

Midrex Technologies and Kobe Steel have developed and optimized Shaft Furnace Simulated Condition (SFSC), a labora-tory test under non-isothermal and non-constant gas composition conditions that can vary the initial reduction tempera-ture so the microstructure of the reduced sample resembles that of industrial DRI using a specially designed furnace. The reduction characteristics, metallization, and mechanical properties obtained from SFSC testing were compared with those obtained from an extended R90 test (iso-thermal and constant gas composition conditions) and from an industrial DR plant, using various oxide pellets, with the following results:

1. The Reduction Rate in the extended R90 test was faster than in SFSC test, while the final Reduction Degrees were in same range.

2. The Metallization results obtained from the SFSC test showed good agreement with that of the industrial DRI. Therefore, it can be said that the SFSC test is similar to the reducing condition in an actual DR plant.

3. The Swelling Index of the extended R90 test was the highest and different from those of the SFSC test and industrial DRI; i.e., the oxide pellets expanded significantly, in an unnatural way.

4. The Cold Crushing Strength obtained in the SFSC test was higher than that of industrial DRI, possibly due to the sintering of iron particles in the DRI.

5. There was a recovery of strength in accordance with the progress of reduction in the SFSC test.

Therefore, it can be said that SFSC testing is a valid measurement of the reduction characteristics and mechanical properties of DRI.

This article was developed from the paper titled, “Mechanical Properties of Direct Reduced Iron (DRI) Reduced Under a Simulated Shaft,” presented at AISTech, May 5-8, 2025, in Nashville, TN, USA, by Katsuma Fujiwara of Midrex Research & Development Technology Center.

References

- Mizutani, M., Nishimura, T., Orimoto, T., Higuchi, K., Nomura, S., Saito, K., Kasai, E., Influence of Reducing Gas Composition on Disintegration Behavior of Iron Ore Agglomerates, ISIJ International, Vol.57, 2017, pp. 1499-1508.

- Zhao, Z., Tang, J., Chu, M., Wang X., Zheng, A., Wang, X., Li, Y., Direct reduction swelling behavior of pellets in hydrogen-based shaft furnaces under typical atmospheres, International Journal of Minerals, Metallurgy and Materials, Vol. 29, 2022, pp. 1891-1900.

- Laforest, G., Dubé, M., Lacroix, O., ON THE DIFFERENCE BETWEEN ISOTHERMAL AND NON-ISOTHERMAL REDUCTION TESTS: A COMPARISON BETWEEN COREM R180 AND ISO DR90, 7th Brazilian Ore Agglomeration Conference proceedings, 2019 (https://abmproceedings.com.br/en/article/on-the-difference-between-isothermal-and-non-isothermal-reduction-tests-a-comparison-between-corem-r180-and-iso-dr90).

Appendix