The IMSBC Code: Regulatory framework for international shipment of solid bulk cargoes

INTRODUCTION

International maritime shipment of solid bulk cargoes is governed by the London-based International Maritime Organization (IMO), a specialized agency of the United Nations that is responsible for measures to improve the safety and security of international shipping and to prevent marine pollution from ships. The IMO sets standards for the safety and security of international shipping. It oversees every aspect of worldwide shipping regulations, including legal issues and shipping efficiency.

The International Convention for the Safety of Life at Sea, 1974 (SOLAS Convention), as amended, deals with various aspects of maritime safety and contains, in chapter VI, the mandatory provisions governing the carriage of solid bulk cargoes. These provisions are extended in the International Maritime Solid Bulk Cargoes Code (IMSBC Code). The primary aim of the IMSBC Code is to facilitate the safe stowage and shipment of solid bulk cargoes by providing information on the dangers associated with the shipment of certain types of solid bulk cargoes and instructions on the procedures to be adopted when the shipment of solid bulk cargoes is contemplated.

CLASSIFICATION OF DRI PRODUCTS

The IMSBC Code, which replaced the Code of Safe Practice for Solid Bulk Cargoes (BC Code), came into legal effect in 2011 and is updated every second year, the current edition being the 2020 edition. Appendix 1 of the code contains individual schedules for more than 300 solid bulk cargoes, including three types of Direct Reduced Iron (DRI).

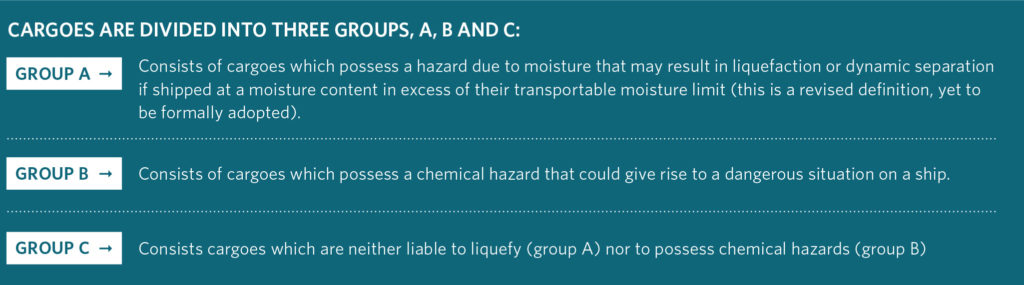

A sub-set of Group B cargoes is Materials Hazardous only in Bulk (MHB). These are materials that when carried in bulk, possess chemical hazards other than the hazards covered by the classification system of the International Maritime Dangerous Goods Code. These materials present a significant risk when carried in bulk and require special precautions. Such hazards are Combustible solids (CB), Self-heating solids (SH), Solids which evolve flammable gas when wet (WF), Solids which evolve toxic gas when wet (WT), Toxic solids (TX), Corrosive solids (CR) and Other hazards (OH).

IMSBC Code schedules include sections for description, characteristics, hazard, hold-cleanliness, stowage and segregation, weather precautions, loading, precautions, ventilation, carriage, discharge, clean-up and emergency procedures.

The three forms of Direct Reduced Iron (Hot Briquetted Iron (HBI), DRI, and HBI/DRI Fines) are classified as MHB SH and/or WF (WF relates to evolution of hydrogen).

The three schedules for the three forms of Direct Reduced Iron are:

- Direct Reduced Iron (A) Briquettes, hot-moulded (this is HBI and is Group B)

- Direct Reduced Iron (B) Lumps, pellets, cold-moulded briquettes (this is DRI and is Group B)

- Direct Reduced Iron (C) (By-product fines) (this is DRI/HBI Fines and is Group B)

Self-heating occurs as a consequence of the re-oxidation of DRI, a mainly exothermic reaction, and if not controlled can lead to ignition of the cargo. This hazard is especially the case for DRI (B) due to its porous or spongelike structure and, when in a cargo hold, the large surface area accessible to air/oxygen.

Evolution of hydrogen occurs when DRI comes into contact with moisture/water, especially seawater, the reaction mechanism being the aqueous corrosion of iron.

DESCRIPTIONS & HAZARD PROFILES

The IMSBC Code schedules for DRI contain the following description and hazard profiles:

DRI (A): A metallic grey material, moulded in a briquette form, emanating from a densification process whereby the DRI feed material is moulded at a temperature greater than 650oC and has a density greater than 5,000 kg/m3. Fines and small particles (under 6.35 mm) shall not exceed 5% by weight. A loading requirement for DRI (A) is that moisture content shall be <1%.

Hazard: Temporary increase in temperature of about 30oC due to self-heating may be expected after material handling in bulk. The material may slowly evolve hydrogen after contact with water (notably saline water). Hydrogen is a flammable gas that can form an explosive mixture when mixed with air in concentration above 4% by volume. It is liable to cause oxygen depletion in cargo spaces. This cargo is non-combustible or has a low fire risk.

DRI (B): A highly porous, black/grey metallic material formed by the reduction (removal of oxygen) of iron oxide at temperatures below the fusion point of iron. Cold-moulded briquettes are defined as those which have been moulded at a temperature less than 650oC or which have a density of less than 5,000 kg/m3. Fines and small particles under 6.35 mm in size shall not exceed 5% by weight.

Hazard: Temporary increase in temperature of about 30oC due to self-heating may be expected after material handling in bulk. There is a risk of overheating, fire and explosion during transport. This cargo reacts with air and with fresh water or seawater to produce heat and hydrogen. Hydrogen is a flammable gas that can form an explosive mixture when mixed with air in concentrations above 4% by volume. The reactivity of this cargo depends upon the origin of the ore, the process and temperature of reduction, and the subsequent ageing procedures. Cargo heating may generate very high temperatures that are sufficient to ignite the cargo. Build-up of fines may also lead to self-heating, auto-ignition and explosion. Oxygen in cargo spaces and enclosed spaces may be depleted.

DRI (C): A porous, black/grey metallic material generated as a by-product of the manufacturing and handling processes of DRI (A) and/or DRI (B). The density of DRI (C) is less than 5,000 kg/m3. A loading requirement for DRI (C) is that the moisture content must be <0.3%.

Hazard: Temporary increase in temperature of about 30o due to self-heating may be expected after material handling in bulk. There is a risk of overheating, fire and explosion during transport. This cargo reacts with air and with fresh water or seawater, to produce hydrogen and heat. Hydrogen is a flammable gas that can form an explosive mixture when mixed with air in concentrations above 4% by volume. Cargo heating may generate very high temperatures that are sufficient to lead to self-heating, autoignition and explosion. Oxygen in cargo spaces and in enclosed adjacent spaces may be depleted. Flammable gas may also build up in these spaces. All precautions shall be taken when entering cargo and enclosed adjacent spaces. The reactivity of this cargo is extremely difficult to assess due to the nature of the material that can be included in the category. A worst case scenario should therefore be assumed at all times.

Each schedule details the precautions to be taken to mitigate the risks associated with the hazards of the cargo in question. For all types of DRI, monitoring of the cargo temperature and hydrogen concentration are essential. In all cases, material with temperature > 650oC shall not be loaded.

For DRI (A), the Ventilation section states: surface ventilation only, either natural or mechanical, shall be conducted, as necessary, during the voyage for this cargo. On no account shall air be directed into the body of the cargo. When mechanical ventilation is used, the fans shall be certified as explosion-proof and shall prevent any spark generation, thereby avoiding the possibility of ignition of hydrogen-air mixture. Suitable wire mesh guards shall be fitted over inlet and outlet ventilation openings. Ventilation shall be such that escaping gases cannot enter living quarters in hazardous concentrations.

For DRI (B), the Loading section states: prior to loading, provision shall be made to introduce a dry, inert gas at tank top level so that the inert gas purges the air from the cargo and fills the free volume above. Nitrogen is preferred for this purpose. All vents, accesses and other openings, such as coaming drains, that could allow the inert atmosphere to be lost from cargo spaces carrying this cargo shall be closed and sealed.

The Precautions section states: the ship shall be provided with the means to ensure that the requirement of this Code to maintain the oxygen concentration below 5% can be achieved throughout the voyage. The ship’s fixed CO2 fire-fighting system shall not be used for this purpose. Consideration shall be given to providing the vessel with the means to top up the cargo spaces with additional supplies of inert gas, taking into account the duration of the voyage.

The Ventilation section states: the cargo spaces carrying this cargo shall remain tightly sealed and the inert condition maintained during the voyage.

The precautions and measures for DRI (C) are essentially the same as for DRI (B). With respect to DRI Fines, it is important to note that the vast majority of shipments of this material contain moisture content in excess of the maximum 0.3% required for DRI (C), typically 5-6%, but in any case less than the transportable moisture limit. For such material, the principal hazard is evolution of hydrogen rather than self-heating. Therefore, shipments have for many years and continue to be covered by exemptions in accordance with section 1.5 of the IMSBC Code which permit the higher moisture content and require mechanical ventilation as the principal methodology for dealing with the hydrogen hazard, a practice safely employed by the industry for many years.

For the last ten years or so, attempts have been made at the IMO to introduce a new IMSBC Code schedule for DRI Fines with higher moisture, embodying mechanical ventilation as the principal safety precaution. Concerns about the effectiveness of ventilation have been raised and, underlying this process are long memories of past incidents with DRI Fines, notably the tragic loss in 2004 of six lives and the M/V Ythan, a bulk carrier en route from Venezuela to Asia with a full cargo of DRI Fines. Industry, working collaboratively through IIMA, co-sponsored an updated draft schedule, designated DRI (D), together with Canada and the USA, which is currently going through the IMO process (much delayed by the COVID-19 crisis). IIMA can provide further information.

The IMSBC Code can be purchased in hard copy or electronic format via the IMO website. At the time of writing, the text of the 2020 version of the IMSBC Code can be downloaded here.