DRI is the steel industry’s most flexible metallic charge material, and the MIDREX Process can produce, discharge and transport DRI in the form best suited to the application.

MIDREX® Plants can be designed to switch from one DRI form to another with no disruption of product flow – CDRI to HBI, CDRI to hot DRI (HDRI), or HDRI to HBI. Product can be produced simultaneously in any combination.

Types of DRI

Cold DRI (CDRI)

Most MIDREX® Plants built to-date produce CDRI. After reduction, the DRI is cooled in the lower part of the MIDREX® Shaft Furnace to about 50° C. This material is typically used in a nearby EAF and passivated to prevent reoxidation and loss of metallization. CDRI is ideal for continuous charging to the EAF.

Types of DRI

Hot DRI (HDRI)

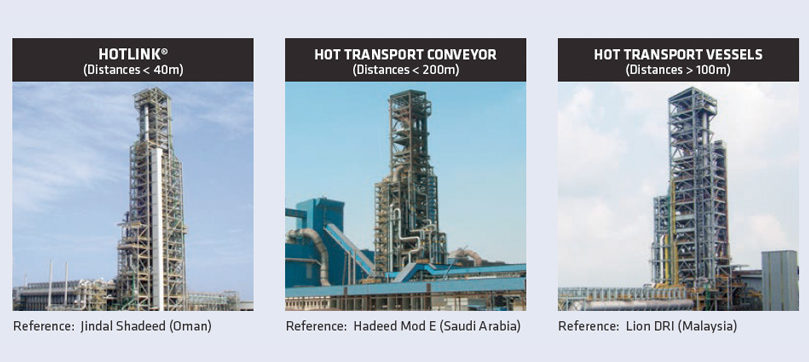

DRI can be transported to an adjacent EAF at up to 650° C to take advantage of the sensible heat, which allows the steelmaker to increase productivity and reduce production cost. Midrex offers three methods for HDRI transport: hot transport conveyor, hot transport vessels, and HOTLINK®.

Hot transport & charging methods

In EAF steelmaking, hot transport/hot charging is an effective means of lowering the cost per ton of liquid steel by reducing power and electrode consumption, as well as increasing EAF productivity.

MIDREX Shaft furnaces can be equipped with one of three systems to transfer HDRI to a steelwork’s meltshop: HOTLINK, Hot Transport Conveyor (HTC) and Hot Transport Vessel (HTV).

Midrex Hot Charging Methods

In a MIDREX® Hot Discharge Plant, HDRI can be transferred by one of three methods to an EAF meltshop:

Types of DRI

Hot Briquetted Iron (HBI)

HBI is the preferred DRI product for the merchant metallics market because it is much denser than CDRI, which reduces the reoxidation rate and minimizes yield losses from breakage. This enables HBI to be stored and transported without special precautions under the International Maritime Organization (IMO) code for shipping solid bulk cargoes. It can be used in the EAF, BF, and BOF. HBI is made by compressing DRI discharged from the MIDREX® Shaft Furnace at ≥ 650° C into pillow-shaped briquettes with a typical size of 30 x 50 x 110 mm and a density ≥ 5 g/cm3. No binder is used to make HBI.