“Happy Trails, ‘Til We Meet Again”

I have had the pleasure to be associated with Direct From Midrex (DFM) since its reintroduction in 3Q1981, which we labeled Fall 1981 before realizing that fall in Charlotte is spring somewhere else. As editor from 1981-1993, and a consultant/contributor since 2013, I was involved in transforming what was a sporadically published collection of Midrex patents and company news into the quarterly journal of direct reduction it is today. I want to thank current DFM editor, Lauren Lorraine, for allowing me to reminisce about my 24- year association with Direct From Midrex.

If you were around in 1981, you probably remember when MTV was launched, the home PC was introduced (Commodore 64 with 64kb of RAM!), Britain’s Prince Charles and Lady Diana Spencer were married, and former Hollywood actor, Ronald Reagan, became President of the United States. It also was the year that I joined Midrex.

I worked for GE (General Electric) in various marketing communications and public relations roles from 1972-1981, after serving four years as a U.S. Army officer. However, I was tired of being a small part of a huge organization and began looking for other opportunities, preferably in the South closer to where I grew up and went to college (Chattanooga, TN). So, I answered an ad in a public relations trade magazine for a marketing communications manager in Charlotte, NC, for a company called Midrex that was involved in something known as direct reduction in the steel industry.

Pictured: Frank's initial 1981 issue of Direct From Midrex (DFM) / present day DFM issue

In 1981, direct reduction and direct reduced iron (DRI) were primarily associated with start-up steel industries in emerging economies. In fact, back then DRI was typically used as a “price buster” for scrap and made up only a small percentage of the electric arc furnace (EAF) charge, if at all. Total DRI production in 1980 was 7.13 million metric tons (Mt), with MIDREX® Plants producing 56% (3.96Mt) of the total. Compare that with 140.8 Mt of global DRI production in 2024, and it’s easy to see how far the industry has come. Similarly, MIDREX Plants accounted for 76.2 Mt of all forms of DRI in 2024.

Personal computers were starting to replace electric typewriters and cell phones were still somewhere in the future when I joined Midrex, so there was no such thing as social media. As a result, we published a company newsletter called “Pellet Talk” off-and-on for several years. Midrex employees relied on talking with each other and the company bulletin board to stay informed. Today, Midrex has available a host of sophisticated internal communications tools (thanks to Lauren Lorraine’s vision and expertise) designed to support all levels of internal messaging, from executive updates to more casual employee updates.

“Through the years, DFM has remained true to its mission – be the journal of direct reduction.“

Another aspect of Midrex life was the roller coaster business cycles of the steel industry. Within six months of joining the company, we were plunged into a steel industry downcycle that depressed prices for scrap, DRI, and steel. It lasted until mid-1988, and Midrex was forced into layoffs after staffing up to meet increased business demands in the mid-to-late 1970s. The second downcycle struck in late 1991, but lasted only until mid-1994. The recovery that time looked like it would last forever, but the bottom fell out again in 1998-1999, and by the beginning of 2002, Midrex was down to a core of 50 employees. The steel industry recovered after a few tough years and continues to spur industrial and economic growth. Likewise, Midrex, true to its nature, weathered the storm and has prospered and grown stronger today than ever before.

Through the years, DFM has remained true to its mission – be the journal of direct reduction. Nothing exemplifies this more than the role it played in the 1990s, promoting the idea that DRI should be treated as a supplement to scrap rather than an alternative, with an intrinsic value that far exceeds price alone. Today, not only are EAFs producing the highest quality steel grades by including significant percentages of DRI in the charge, blast furnace (BF) operators are using hot briquetted iron (HBI) to increase productivity while reducing carbon dioxide (CO2) emissions. And DRI is widely regarded as the most effective way to achieve net-zero emissions in iron and steelmaking.

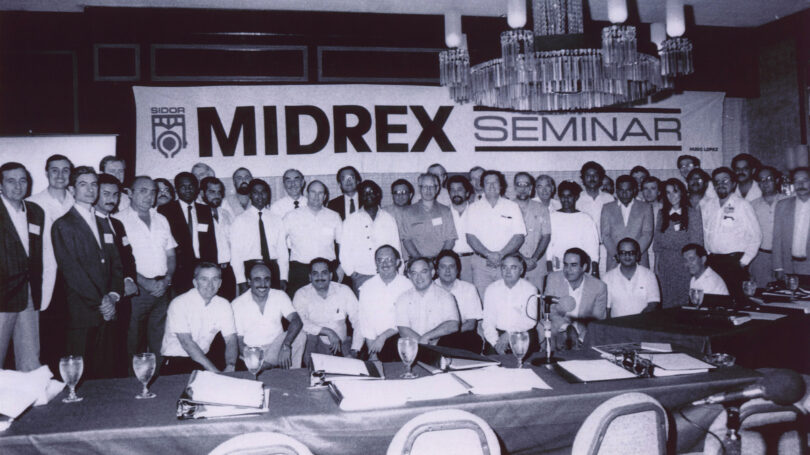

Pictured: Frank Griscom at the 1988 Midrex Operations Seminar in Venezuela.

DFM, as it has for almost 45 years, is promoting the role of DRI in the evolution of the global steel industry by publishing articles that report on leading edge research and testing at the Midrex Research & Technology Development Center, operational achievements by the global family of MIDREX Plants, and featuring commentaries that provide insights and opinions on industry issues.

I have been fortunate to meet, work with, and become friends with many fantastic people during my 40+ years in and around Midrex including Robert Hunter, John Kopfle, and Shohei Manabe. Unfortunately, some of them are no longer with us – Roy Ogden, Franz Sammt, and Don Lyles. Their wisdom, determination, and character are woven into the rich fabric of Midrex and continue toinspire those of us who knew them and all those who follow in their footsteps.

Every phase of my working career – US Army officer, newspaper sports reporter, GE publicist and marketing communications manager, Midrex marketing & sales executive, and iron & steel industry trade association director – has had a formative role in my personal beliefs and principles: be a leader, not a follower; set an example and live it; focus on contributed value; be a promoter not the star. Whatever I have achieved is directly attributable to them, and the enduring role of Direct From Midrex in promoting a sustainable future for the global steel industry is my proudest legacy.

Just as old-time cowboy star Roy Rogers would say as he prepared to ride off into the sunset, “Happy trails, ‘til we meet again.”