Creating a Culture of Success: Performance & Achievements of AQS

Introduction

Algerian Qatari Steel (AQS) was established in December 2013, as a joint venture between Qatar Steel International (49%), SIDER Investment Group (46%), and the Algerian National Investment Fund (5%). The relations between Algeria and Qatar are longstanding and growing, highlighted by decades of co-operation and synergy in economy and trade, industry, energy, mining, agriculture, and social and political initiatives.

AQS operates a 2 million metric tons per year (Mt/y) steel mill in the industrial zone of Bellara, in El-Milia, an administrative district of Jijel, located 400 km from Algiers. The steel complex occupies a total area of 216 hectares (> 553 acres) and includes:

- MIDREX® Direct Reduction Plant – production capacity of 2.5 Mt/y hot and cold direct reduced iron (HDRI and CDRI)

- Two 120-ton electric arc furnaces (EAFs) – total production capacity of 2.2 Mt/y

- Three rolling mills – total production capacity of 2 Mt/y of reinforcing bars and wire rod

Supporting these production units are an industrial gas plant, lime production unit, station for receiving & transporting raw materials, water treatment plant, and electrical substation.

The AQS project was launched in March 2015. The first rolling mill (for reinforcing bars) and the water treatment plant began operation in 2017. In 2018, the complex continued to take shape with start-up of a second rolling mill (for wire rods) and the industrial gas plant, and SNTF (The National Rail Transportation Company) completed installation of a line between the plant and the international port. The third rolling mill and the first EAF were put into service in 2019, followed by the second EAF and the MIDREX Plant in 2020, and the air separation plant, lime plant, and the materials handling system in 2021.

AQS Midrex Combination (CDRI-HDRI) Plant

First direct reduced iron (DRI) was produced in February 2021, and HDRI was initially charged to the EAF in March 2021. The AQS direct reduction plant (DRP) achieved its hourly design capacity (312 t/h) in September 2021, and was operating at 9% over design capacity by March 2022. During its first full year of operation (2022), 74% of total production (1.7 Mt) was HDRI in response to melt shop demand. In 2024, the HDRI-to-CDRI ratio was 63%-to-37%, with average HDRI metallization 94%, metallic iron content 85%, and product carbon 2.5% (max monthly average up to 2.77% in March). AQS shipped 80,000 metric tons of CDRI to customers in the region.

The AQS DRP is equipped with an enclosed and insulated metallic conveyor for feeding HDRI to the EAF melt shop. The HDRI is delivered to bins at 580° C (average) for direct charging to the EAF to ensure there are no fugitive dust emissions.

The transporting and feeding system is designed so HDRI and CDRI can be mixed at the discretion of the melt shop or HDRI can be diverted to a product cooler and stored as CDRI. During 100% HDRI production, some “trickle discharge” is maintained to avoid static DRI at the product cooler.

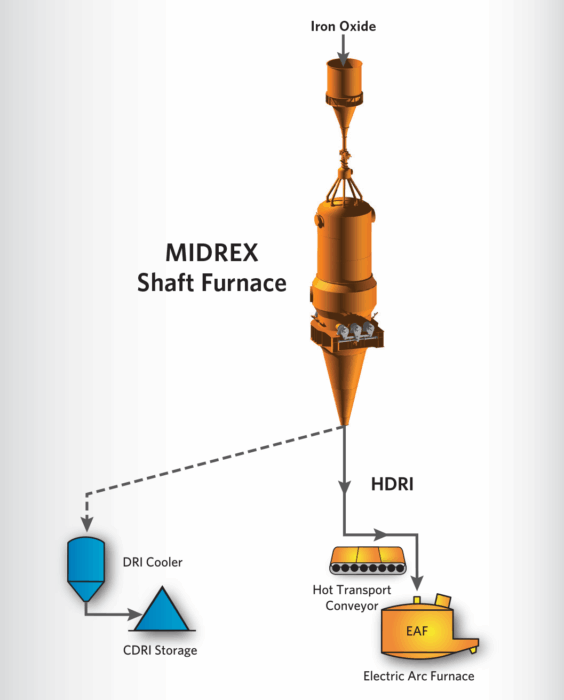

FIGURE 1.

Reduction furnace product discharge options

The product discharge arrangements (see Figure 1) allow AQS to produce HDRI and CDRI from the same shaft furnace. Therefore, when the melt shop does not require HDRI, the material can be cooled and stored for shipment as CDRI throughout the MENA region.

To ensure a continuous and secure supply of high-quality (DR-grade) iron oxide pellets, AQS utilized multiple sources during 2024 and is planning to install a desulfurization unit. This unit will enable the use of pellets with higher sulfur content without adversely affecting the catalyst, which will significantly reduce raw material costs while maintaining product quality and process stability.

AQS Direct Reduction Plant (DRP)

Capacity (rate)

Annual: 2.5 Mt

Daily: 7,500 t

Hourly: 312.5 t

DRI Products (at bins)

Metallization: 94%

Metallic Fe: 85%

Carbon: 2.55%

HDRI Temperature: 580° C

Operating Hours (rated): 8,000 Hrs

Feed: DR-grade Fe oxide pellets (up to 5% low-grade Fe pellets)

Shaft furnace diameter: 7.65 m

Reformer tubes: 720, 11” dia.

Reformer bays: 18 bays

Reformer rows (per bay): 8 rows

Steadily Increasing Performance

From the outset, AQS has been committed to continuous improvement, guided by four strategic priorities: safety, production, quality, and problem-solving. Creating a culture of cooperation and adherence to established work procedures and safety instructions, advocating for team training, and learning from past experiences have contributed to maintaining a safe work environment and steadily improving performance and quality.

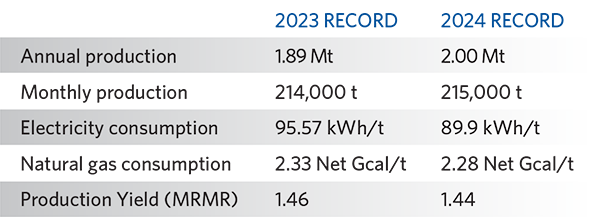

AQS DRP received three awards during the 2024 International Conference on MIDREX Technology in recognition of outstanding operational excellence in 2023, when the plant set three local plant records: 7,208 operating hours, 1.8 Mt annual production volume, and 95.6 kWh/t electricity consumption.

It is worth noting that all the plant records achieved in 2023 were broken in 2024, as AQS DRP set new annual production volume, electric power consumption, natural gas consumption, and production yield milestones (see Figure 2). These figures demonstrate steady advancement of the DRP team on the plant operation and maintenance learning curve.

FIGURE 2.

AQS DRP performance

In 2024, the DRP produced approximately 2.0 Mt of DRI, the highest annual production volume since start-up in 2021 (see Figure 3), demonstrating consistent progress along the learning curve and a positive trajectory. 2024 was impacted by a number of issues, which in cooperation with Midrex Global Solutions are being successfully focused on during 2025. Through July 2025, the plant is running at design tonnage with ongoing efforts for improvement of furnace feed conveyor reliability and operational practices of the reformer. The timing between carbon burnouts has increased from ~1 month to 3+ months without addition of any natural gas pretreatment to remove heavy hydrocarbons. Throughout the first half of 2025, AQS has produced 1.11 Mt of DRI and is targeting an annual total of 2.5 Mt of DRI , with consistent product quality targeted at metallization of 94% and carbon content averaging 2.5%

FIGURE 3.

Annual DRI production since start-up

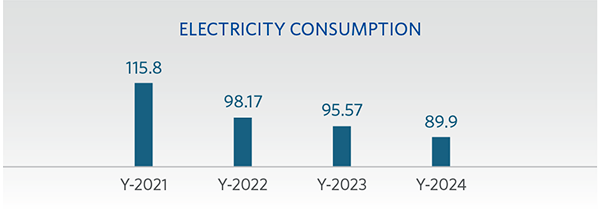

Electricity consumption has been reduced by more than 25% since AQS DRP was started up in 2021 (see Figure 4).

FIGURE 4.

Electricity consumption since start-up

In keeping with AQS’s customer-centric approach, DRP ensures that its customers – be they internal or external – receive consistently high product quality. Carbon content has been boosted every year since initial start-up and has averaged ˃2.5% since 2024 (see Figure 5), and metallization has been maintained at 94%.

FIGURE 5.

Carbon content of DRI since start-up

In October 2024, DRP conducted a planned annual shutdown during which several key maintenance milestones were achieved: replacement of the oxide feeding conveyor, thorough cleaning of the water system, shaft furnace refractory inspection and repairs (with Midrex assistance), eddy-current testing (ECT) and replacement of 100 reformer tubes, and leak testing of the heat recovery bundles.

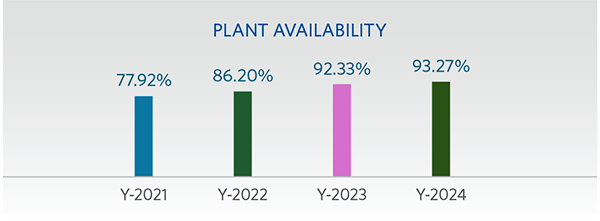

Plant availability has consistently improved since the initial start-up (see Figure 6).

FIGURE 6.

Plant availability since start-up

Midrex Global Solutions and Superdata

Since 2023, AQS DRP has cooperated closely with Midrex Global Solutions, the aftermarket service arm of Midrex, for a range of activities: plant monitoring, pro-active identification and resolution of potential issues, and application of lessons learned. Through more than 50 online meetings, AQS and the Midrex Remote Professional Service (RPS) team have resolved 44 service tickets, which have been instrumental in achieving the outstanding performance record of the DRP.

Beginning in 2023, RPS has used ECT to monitor the AQS reformer tubes. The purpose of this service to determine the life of the tubes, ensure the tubes perform as expected, and identify issues such as tube imbalance or growth. ECT is now performed on an annual basis.

A primary tool used by Midrex RPS is Superdata, which is instrumental in establishing a plant’s process center line utilizing:

- mass and energy balance

- process performance monitoring (reduction furnace, reformer, and heat recovery system)

- furnace gas utilization, reformer productivity/approach to equilibrium, flue gas data

- reductant calculations (based on gas analysis data)

- identifying specific measurements for calibration or other checks.

Superdata – Then and Now

Access to Superdata drives Innovation, identifies process ranges, tracks operational behavior, and facilitates recommendations for improvements. Although Superdata has been available to MIDREX Plant operators for some time, it has had limited use because it was considered too specialized, not user-friendly, time-consuming to learning, and required training, experience, and judgment to use it. However, the Midrex RPS team is digitalizing Superdata to create a powerful plant operation and optimization tool (see Table 1).

TABLE 1.

Midrex Superdata comparison

For further information about Algerian-Qatari Steel Company and its products, visit the AQS website at https://aqs.dz. To learn more about digital Superdata and the other plant performance and optimization solutions from Midrex Global Solutions, visit https://www.midrex.com/global-solutions.